Preventative monitoring of a garbage bunker with an infrared camera end-to-end system. Almost one billion tonnes of waste is generated worldwide each year, which is then disposed of and recycled in many countries via a comprehensive system of waste recycling plants. Heat is often produced in the refuse bunkers, culminating in smouldering nests, which can ultimately cause a devastating fire. An early fire detection system using infrared cameras can promptly detect and remove the hazard.

“Studies show that waste generation is on the rise worldwide. These days waste disposal has to be efficient and resource-friendly. To ensure that this is put into effect in waste incineration plants, we are on hand as a partner with our non-contact infrared measurement technology,” says Luc Lagorce, Sales Director Europe.

Delivery vehicles transport the waste to the recycling plants and tip the material into a refuse bunker. The bunkers have different storage capacities, for example, the plant in Bonn is 14,000 cubic metres holding roughly 7,000 tonnes of waste. Waste storage produces heat, often leading to the formation of smouldering nests. A gripper is used for the automated transport of the waste to the charging hopper, creating heat displacement and physical effects, which may cause a fire in the refuse bunker. As a result, not only is the plant decommissioned for a few hours, but costly clean-up operations or rehabilitation must be carried out as well.

Infrared cameras are able to measure temperature differences and absolute temperatures very precisely. The waste in the garbage bunker can be easily observed 24/7 by integrating the cameras and accessories. This thereby ensures a prompt response to potential hazards. When combined with other detection systems, e.g. traditional smoke detectors, sprinkler systems can be automatically deployed. The ultimate goal is to monitor the entire bunker surface using infrared cameras. The size of the bunker determines the number of cameras used.

Recommended Solution:

Infrared camera Optris PI 640

- The thermal imager Optris PI 640 is the smallest measuring VGA infrared camera worldwide. With an optical resolution of 640x480 pixels, the PI 640 delivers pin-sharp radiometric pictures and videos in real time.

- With a body sized 45x56x90 mm and weighing only 320 grams (lens included), the Optris PI 640 counts among the most compact thermal imaging cameras on the market.

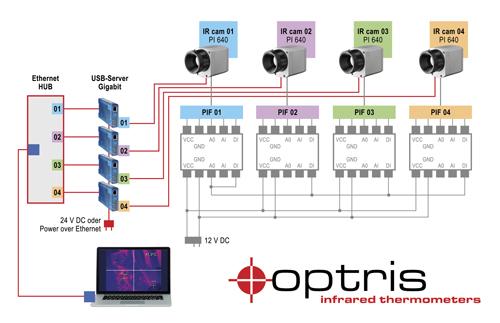

USB Server Gigabit

- Long-distance control of infrared cameras: Acting as a USB to Ethernet adapter, the USB Server Gigabit allows bridging distances significantly longer than 20 meters between the PC and a PI thermal imaging camera and the Optris CTvideo/ CSvideo video pyrometer series.

Integration of thermal imaging cameras in automated processes

- The newly developed industrial process interface (PIF) permits automatic process monitoring, for the continuous in-operation control of the hardware of the PI infrared cameras with all cable connections and the free analysis software PI Connect. An innovation on the market in this monitoring process is the control of the external computer.

For further information please contact:

Tom Aldridge Instrumentation & Measurement Business Unit Manager Phone: 09 526 7557

Email: taldridge@eurotec.co.nz