New Zealand manufacturing Icon, Dotmar Engineering Plastics have increased their support to manufacturers and component designers throughout New Zealand.

When business are faced with premature equipment obsolescence or poor functionality due to worn or broken metal and plastic parts Dotmar can rescue the day.

A recent acquisition is digital measuring equipment from Kreon Technology USA. This very accurate piece of equipment removes all doubt when there is a requirement to measure and model a component.

Curves, tapers, radii, 3D shapes are easily measured and converted to solid files.

Older equipment may often contain obsolete parts and when these break there is no option but to remake them, to do this first they have to be accurately measured and drawn. Often when the worn, damaged or prototype components have to be copied it is discovered any drawings are possibly long gone or the original manufacturer closed up years ago and the only references are existing parts.

A regular request is the measurement of components on site, the Kreon is able to be taken to site anywhere in New Zealand and set up to measure parts insitu. The benefits are that the Engineer not only gets accurate measurements to +/-0.01mm but the machine downtime is greatly reduced allowing quick return to production. Examples of where this feature has been utilised include bottling plants, paper mills, mines and anywhere there are large parts that may be difficult to move or transport, fragile or integral to ongoing production. The Kreon has no size limits to what can be measured.

Tool designers who need an accurate drawing file of existing components to begin manufacturing injection, thermoforming or blow moulded dies are finding this technology invaluable in reducing the build phase time by days and weeks whilst still ensuring accuracy is maintained.

The complete measuring service includes providing a solid file in a range of formats from which to manufacture the replacement or copied component.

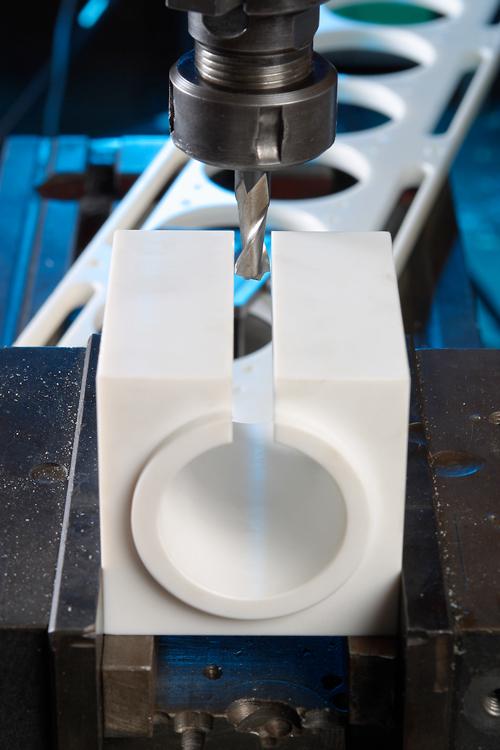

Dotmar throughout New Zealand specialise in the manufacture of multi axis, low volume, machined plastic components for marine, production, aeronautical, packaging and associated industries.

Contact 0800 650 750