Amatek Land has collaborated with iba AG, a provider of comprehensive process analysis software, to expand process connectivity and production insights.

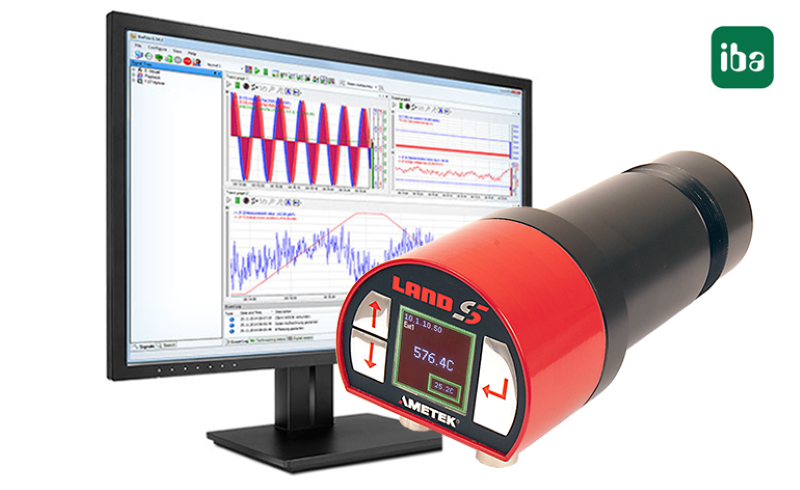

By working together, the two companies aim to revolutionise process visualisation and optimisation by seamlessly integrating LAND’s SPOT+ pyrometers with iba’s powerful ibaPDA platform. This collaboration will allow manufacturers to gain unprecedented insights into a range of their production processes.

The challenge lies with processing materials like metals or paper where high temperatures and significant energy consumption are involved. Ametek Land’s SPOT+ range allows for temperatures to be precisely and flexibly measured, even in demanding applications such as aluminium and metals processing.

The new interface with ibaPDA allows the temperature readings to be analysed in the iba system. By combining the high-resolution data from SPOT+ pyrometers with other critical process parameters captured by ibaPDA, companies can gain a comprehensive understanding of how the temperature affects overall production efficiency and quality.

In addition, it identifies optimisation opportunities by uncovering areas where adjustments can be made to improve process performance and reduce costs. It will also enhance decision-making, using data to optimise production, minimise downtime and improve product quality.

Derek Stuart, Global Product Manager at Land said: “We are excited to be partnering with iba to deliver a solution that empowers manufacturers to achieve new levels of process efficiency and control. By combining the precision of SPOT+ pyrometers with the versatility of ibaPDA, we are providing customers with a powerful tool to optimise their operations and drive continuous improvement.”