Bonfiglioli’s Sydney factory is expecting the delivery of a new heavy-duty (HD) gearbox assembly machine early next year, which will double output and improve lead times.

According to Kris Jaryn, Bonfiglioli’s National Manager of HD and Planetary, this investment enables the company to meet growing industry demand for HD solutions – the fastest growing sector in the company- “This new machine will allow us to quote shorter delivery times for customers.”

Currently, the assembly process – including testing and painting of bevel-helical gearboxes (which weigh at least a tonne each) – takes up to four days. “Our Sydney plant processes units regularly each week. With the new machine, which is now enroute to Australia, we are looking at delivery of around ten gearboxes each week,” says Kris.

HD market growth

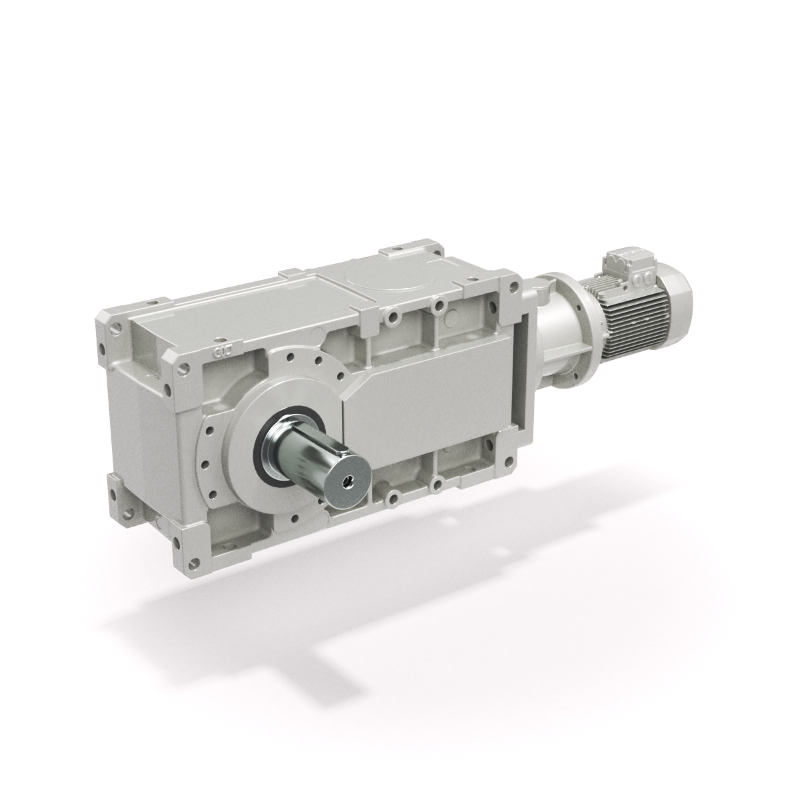

Bonfiglioli HD gearboxes are utilised mainly in heavy industry, including mining, cranes and winches, and material handling. “85% of our gearboxes are used for over-land and underground conveyors, which can be several kilometres in length,” adds Kris.

The majority of customer demand is from the mining sector. These products are installed in coal, gold, iron ore and even lithium mines based locally and abroad. “We are about to send 12 HD gearboxes, which were assembled in Italy, to a lithium mine in Africa. And soon we’ll send another 12 complete conveyor drive assemblies to Perth,” says Kris.

The gearboxes are generally assembled in company’s 5,000m2 Sydney factory, using components shipped from Europe. However, when handling multiple large orders, Bonfiglioli will build the gearboxes in Italy or Slovakia to avoid the delays imposed by space or labour constraints.

By combining planetary and bevel-helical gearboxes that can deliver high ratio with high output torque for specific processes, Bonfiglioli has established a niche in the market.

Supporting local industry

Kris explains that after COVID-19, industry players struggled with stock volumes, and this occasionally resulted in issues with delivery. “This prompted us to increase our local stockholding and to send simultaneous large orders to Europe to save on time.”

Bonfiglioli currently holds about $15 million worth of stock at its Sydney premises, and this includes components for heavy duty gearboxes.

“We offer the market high quality products and have a good local presence with local expertise and service,” concludes Kris. “We look forward to the improved delivery times that the new assembly machine will afford us”.