A hard-wearing chemically-resistant engineering thermoplastic is being introduced to Australasia by Cut To Size Plastics focussed particularly on machine building applications and production of machinery components used in food, beverage and agricultural processing and production of precision medical, electrical and electronic components.

The latest Wearace copolymeric acetal offers the low coefficient of friction and good wear properties required in machinery and components being developed for production automation and Industry 4.0 applications, as well as uses in logistics, materials handling, bottle and car washing equipment, electrical and electronics production, sports equipment, textile processing and office machinery.

Cut To Size Plastics Managing Director Laurie Green says the versatile top quality acetal is formulated by a global producer with 70 years’ experience, Zellamid, whose copolymeric 900 formulation is very timely for Australasian and Asia-Pacific manufacturers and processors focussed on hygienic, easily maintained and easily washed down machinery, components and good OH&S practices often in aggressive environments.

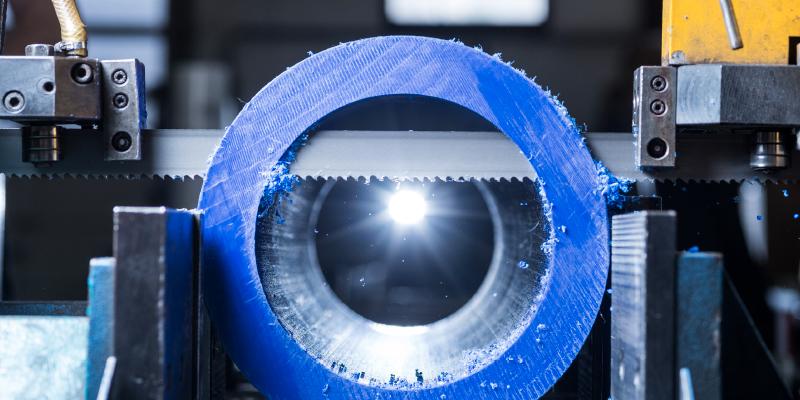

“Tough, light and hygienic materials will become highly relevant to a post-COVID world, in which manufacturers switch production emphasis in line with demand and supply chain fluctuations. Easily machined and readily available parts will increasingly be part of the processing mix,” says Green, whose company has invested in a high-speed, vibration-free Italian Morbidelli Author M100F heavy-duty CNC router and machining centre which offers unmatched finishing quality and rapid production turnaround for the company’s Australasian and Asia-Pacific markets.

Green says semicrystalline thermoplastic POM (Polyoxymethylene) offers good resistance to a wide range of chemicals – including many solvents – as well as the high mechanical strength, heat resistance and good anti-friction properties needed for higher-speed production. It also provides high strength and stiffness, coupled with easy machineability.

“For parts which need to be dimensionally stable, even when exposed to humidity or wet environments, this copolymeric acetal offers better hot water, thermal and chemical resistance than homopolymeric acetal.”

The latest product in the Wearace acetal range is produced according to ASTM D 6100. It is porosity free and most formulations are approved for contact with food (BfR, FDA and EU 10/2011 compliant). Cut To Size Plastics can draw upon its 40 years’ experience to suggest the best formulation for particular applications, as well as providing access to anti-static formulations where these are required for electrical and electronic applications,” says Green.

Details, Email: sales@cuttosize.com.au,

www.cuttosize.com.au