IN WHAT is thought to be the largest system of its kind in the world, Haden & Custance recently designed and manufactured a de-palletising and de-cartoning system for a client’s process line that handles some 100,000 tonnes of product per year.

Ken Woodward, manager of Haden & Custance reports that the manufacturing and workshop pre-commissioning of the equipment was completed during February and site installation had already commenced.

The system includes three ABB IRB6650 six-axis robots each selecting and de-palletising up to three 20kg units of product simultaneously. One robot also controls and stacks three types of empty pallets and layer boards for reuse.

Each ABB robot is fitted with a 17-zone vacuum head that enables the picking and placement of individual or multiple cartons from ten in-feed pallet conveyors.

Each in-feed pallet may have a different product type that is automatically selected and tracked through 200 metres of conveyors as required by other process lines.

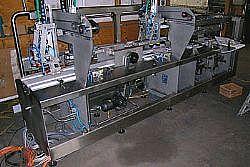

Standard slat conveyors and unique Haden & Custance zero pressure accumulation conveyors transport and track the product to the de-cartoning room.

The automatic de-cartoner is similar to those supplied and operating successfully in Australia, UK and US. It has the capacity to automatically de-carton up to 17 x 20kg units per minute.

After removal of the outer protective carton, plastic wrapped product is conveyed and tracked to additional lines on a combination of stainless slat and chain conveyors. Stainless elevators and de-elevators enable high level conveying to provide easy walking access to each line.

The vacuum sealed plastic bag is removed from each product and the product is then passed to additional process lines by hygienic accumulation conveyors.

In designing the system provision has been included for manual de-palletising and de-cartoning and space is provided for the addition of a fourth robot should output increase.

Custom built De-palletising and de-cartoning system

General

Wednesday, 28 February 2007