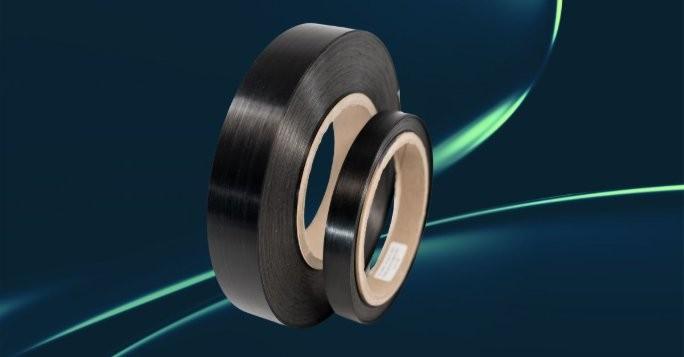

Envalior is launching a new high-performance thermoplastic UD tape for high-pressure all-thermoplastic hydrogen pressure vessels. With UDea® EcoPaXX® Q20HTC60, the manufacturer of high-performance plastics is offering a continuous fibre-reinforced tape, which can be used to wrap and mechanically reinforce polyamide liners. Thanks to the tape, the tank systems can withstand high pressure loads that occur during tank filling and storage.

The UDea EcoPaXX grade is based on polyamide 4.10 and reinforced with 60 percent by weight of unidirectional (UD) continuous carbon fibers. The alternative carbon fibres used in the composite increase the tape’s tensile strength in fibre direction by more than 15 percent to around 2.2 gigapascals (GPa) compared to equivalent materials reinforced with lower strength carbon fibres.

One method to apply the thermoplastic tape is via laser assisted tape placement. This can be done using the start-stop principle, reinforcing the liner only in those areas that are essential to withstand the high pressure. Non-load-bearing carbon fibres can be removed from the composite structure, which cannot be done with the incumbent wet-winding thermoset processing method. This results in weight and cost savings of up to 20%.

More sustainable than traditional thermosetting epoxy systems

A key advantage of the thermoplastic based composite material is its sustainability. Not only is the polyamide 4.10 partly bio-based, but as a thermoplastic composite it is also easy to recycle, in contrast to thermosetting epoxy systems used for pressure vessel winding. These must be landfilled or incinerated at the end of the pressure vessel’s service life. Also, wrapping the liner with the tape does not require any curing or handling of thermoset chemicals for which special occupational safety measures and cleaning protocols are required.

Strong material bonding thanks to high compatibility of polyamide 6 and 4.10

Applying a polyamide 4.10 based tape to a liner made from a polyamide 6 compound causes the laser-generated melts of both polyamides to form a melt-melt contact at the interface, creating a monolithic structure with a strong material bonding.

"Therefore, the liner is not able to deform independently from the composite structure when exposed to mechanical or thermal loads, which results in less risk of buckling and allows for easier cleaning and maintenance of the pressure vessels in service life," adds Perfetti.

Detailed information on Envalior's UDea® EcoPaXX® Q20HTC60 can be found in Envalior's MaterialAdvisor