Compressed air preparation is not exactly a hot topic for plant operators. As a result, carelessly maintained compressed air systems waste energy and result in premature wearing of high-quality pneumatic valves and drives. Festo is now launching a push for greater compressed air efficiency.

Once it gets into the service units, this contaminated compressed air results in faster wearing of seals, oiled-up valves in the control section and dirty silencers. This decreases the availability of the machines and the service life of the pneumatic components and systems and increases the energy costs due to leakage and maintenance effort. Help is available in the form of diagnostic tools, safety functions to ISO and ready-to-install system solutions that Festo combines in a customised and energy-efficient package as appropriate to the requirements of the compressed air systems. Even a few small tricks can together increase the efficiency of the system. These include switching off the air supply when the machines are at rest, when shifts end or during breaks. If greater pressure is needed at specific points in the compressed air network, it is often enough to use a pressure booster at this point instead of operating the entire network with a higher working pressure.

Installing a decentralised compressed air preparation system directly at the system reduces the risk of components being contaminated. Users should clarify the following questions when designing a decentralised compressed air preparation system:

What is the maximum flow rate required?

What connection sizes are required?

Do all consuming devices need the same compressed air quality?

What compressed air quality does the compressor actually provide?

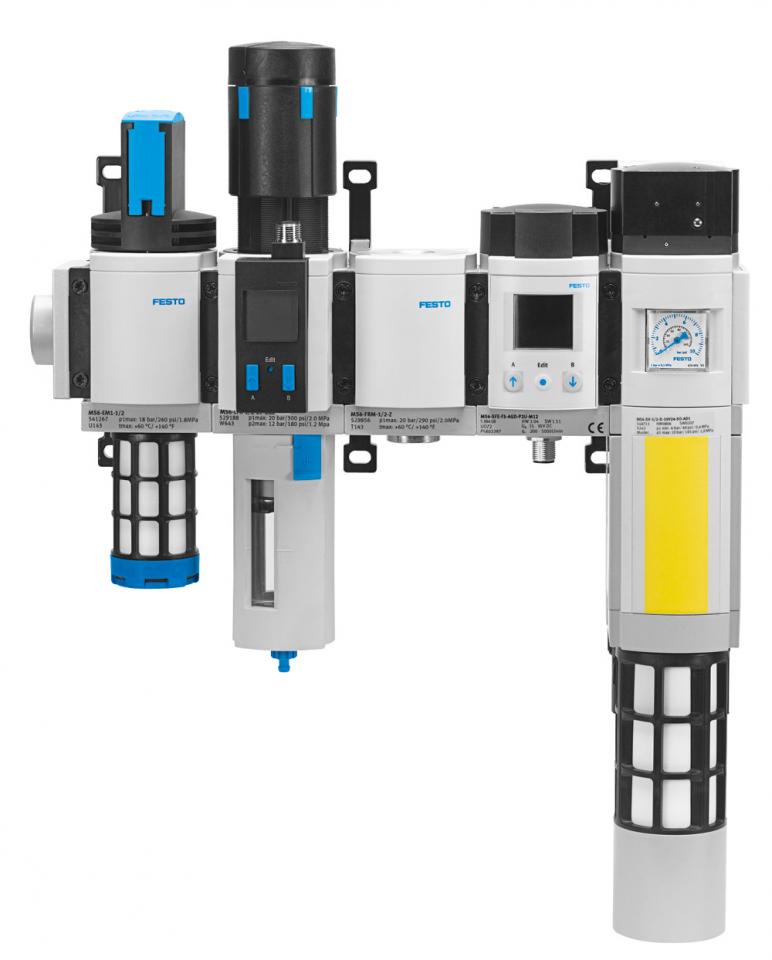

Intelligent service units such as the MS series from Festo integrate flow and pressure sensors that detect unnecessary consumption in good time and enable preventative maintenance. They can also be remotely adjusted and monitored. Pre-assembled solutions for compressed air preparation save users a lot of time and money. These individual solutions with their one part number simplify the design and purchasing process and are supplied ready to install directly at the system.

Compressed air system accessories such as tubing and fittings also deserve attention: tubing materials appropriate to the environment prevent chemical, physical and microbial damage. Festo tubing can be hydrolysis-resistant, flame-retardant, heat-resistant, antistatic or suitable for use in the food industry. When it comes to tubing, it is important to have the correct lengths and diameters to minimise pressure losses as well as to cut them to length using suitable tools. Fittings with modern sealing rings and support functions ensure leakproof and reusable screw connections.

Email: sandra_gargano@au.festo.com