Turck's flush and non-flush mountable, measuring inductive sensors ensure high linearity and easy handling.

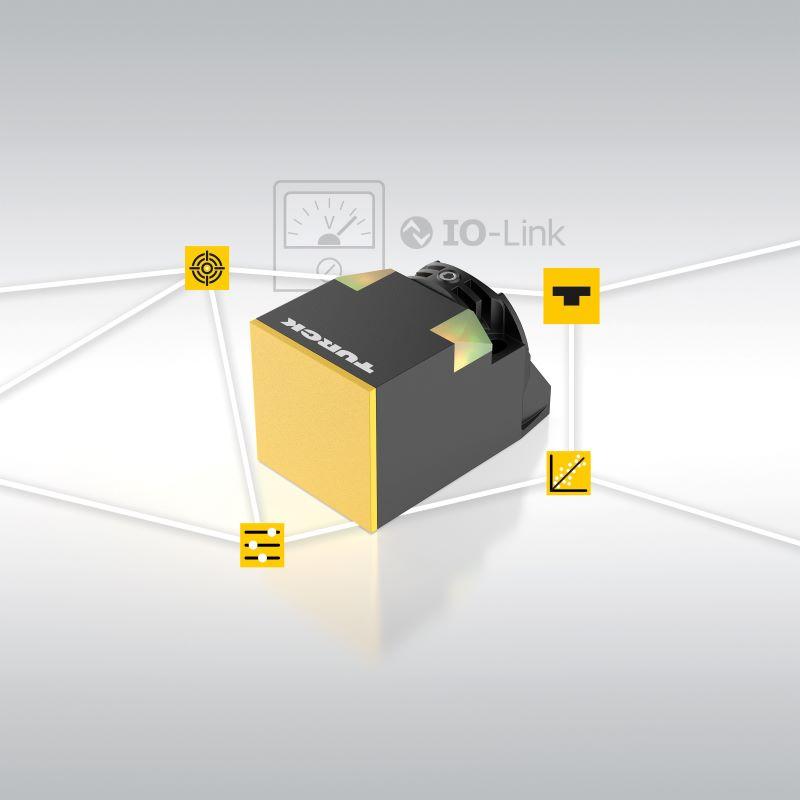

Turck is expanding its sensor range with flush and non-flush mount inductive measuring sensors that have IO-Link and an analog output. Thanks to the integrated microprocessor, the BI11-CK40 and NI11-CK40 models offer significantly improved linearity and accuracy with temperature compensation over a wide temperature range from -25 to +75 °C. The devices are the only sensors of this type to have a standard adjustable 0 to 10 V voltage output as well as an additional switching output that can be freely parameterised via IO-Link, thus providing precise measurement data and extensive diagnostic functions for predictive maintenance.

The simple parameter transfer via IO-Link facilitates sensor replacement in the event of a fault and minimises downtimes in production. With a long range of up to 25 mm and a linearity deviation of less than 1 percent for the flush version and less than 2.5 percent for the non-flush version, the robust IP67 sensors offer maximum precision and reliability in a wide range of applications, for example in the mechanical engineering, packaging, and energy sectors. The proven rectangular CK40 design allows space-saving, flexible and easy-to-implement installation solutions. The sensor head can be positioned easily in five directions using the tool supplied.