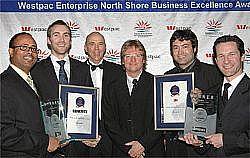

Inveratek Group recently snapped up two wins at the 2007 Westpac Enterprise North Shore Business Excellence Awards: the 3M NZ Excellence in Innovation Award and the Benefitz Best New Start-up Business Award.

The North Shore City-based “ideas factory” company, established in 2003, received the awards in recognition for the development of its ‘CrushPak’ product and its unique approach to business.

Cited by the award judges as “a young, passionate and innovative enterprise on the cusp of big things competing in the global market”, the company’s business is intellectual property (IP). Says chief executive officer Paul Adams: “Intellectual property is the currency of tomorrow.

“Technology is advancing rapidly, social and economic demands are changing, the world is changing. Our client base ranges from individual inventors to multinational corporations; reflecting the reality of a world where IP can originate anywhere and bring value to anyone.”

The company’s four IP core services are advisory services, commercialisation, financing, and licensing. Open files currently in the Inveratek stable include a mix of inventors who approached the company with ideas, corporations and institutions that requested solutions to challenges, and in-house concepts.

Passion and innovation are indeed apt words to describe the attitude of Inveratek’s management team members, comprising: Paul Adams, vice president of research and development Michael Kessell, commercialisation manager Bradley Mitchell and vice president of engineering Edward Scott.

Kessell says the company’s goal is to ensure its clients maximise the value of their intellectual property.

“Most importantly we understand that our clients’ intellectual property is critical to their business - and we maintain the highest professional and ethical standards in every aspect of our practice.”

Mitchell agrees. “At Inveratek we don’t stand on the sidelines. We actively participate in, advise on and fund the creation, development and commercialisation of valuable intellectual capital.

“We bring a depth of understanding and experience to our clients’ needs that comes from first hand involvement in managing intellectual property from its inception to delivery to market. And we measure our results in improved bottom lines, better products and a better future for everyone.”

According to Scott, “Innovation is about adding value and benefits, getting people to do things smarter, in less time at less cost. Our inventions must make the world a better place through technology, and we must feel good about it.”

The team has extensive experience in technology development, industrial design, IP management, patent litigation, and new product introduction.

“This multi-disciplinary, flexible approach allows us to provide a full range of services covering every aspect of IP value creation across the IP life cycle from inception to deal making,” Adams says.

Inveratek’s clients include the world’s largest dairy exporter, a food and beverage company, and marine vessel manufacturer. Local clients include a leading consumer appliance brand, a leading civil engineering firm, a top construction industry software provider, and a leading wireless communications industry solutions provider.

Strict criteria

Mitchell and Scott explain that taking an idea from raw concept to end-user product is a very expensive process and asset evaluation is the first logical step in the chain of services.

“We run the idea past several criteria, the core of our business model. The idea must have a market potential of at least US$50 million, it must be protected or protectable either by trade secret or patent, and we must have the capability to work with it,” Mitchell says.

Scott says it is important that the idea is not a solution looking for a problem.

“Very often people focus on problems that do not exist, or simply take an existing solution and improve it a bit. We don’t do that – it must be an innovation, it must result in benefits to the end-users and it must be simple.”

If the team decides an idea is feasible, it puts in place a strategy that will see the idea progress from 3-D model to commercialisation. This service may include funding. Currently US-based investors fund Inveratek.

“These are people who understand that we’re investing big money for a very long time before we see results – but when the return comes in, the reward is big money, too,” says Adams.

“Our investors also give us access to funding for the development of new ideas and networking in the US and help us get into markets. They understand the dynamics of IP and innovation.”

The cycle follows distinct steps and it may take a year or three before a feasible idea comes to fruition. For example, Kessell conceived the idea for the CrushPak in 2003 when one of his children came running into the kitchen, grabbed a plastic food container from the fridge, half squeezed and half drank the contents and then discarded it, leaving a considerable amount of food still in the bottom.

“I suddenly thought, why not design a plastic container that can easily be squeezed to enable all of the contents to be accessed without a spoon?” he remembers.

The result was CrushPak – an innovative PET container for viscous foods such as yoghurts, jellies, condiments, and sauces. First licensed by Fonterra, the world’s largest dairy exporter, Kessell says CrushPak provided the impetus for Splatz! – a new brand of yoghurt focused on pre-adolescents. The product’s success resulted in Fonterra adding more CrushPak products to its line. A huge ‘green’ benefit is a 25 percent saving on raw material content.

Kessell and Adams started on the product development, making several changes to the core concept. In 2004 Scott entered the scene and using Solid Works 3-D modelling software he created a virtual container the team could study and brainstorm on the whiteboard – applying engineering principles to pull it apart, play around with it, and put it together again.

The resulting 3-D model included specifications for a contractor to cast a physical investment model.

“What we found gave us the confidence to develop our concept into a series of prototype products that showed tremendous potential and were enthusiastically embraced by industry professionals,” says Adams.

From there, another contractor made a revised PET container on a vacuum-forming tool. The product was now ready for a testing regime, including both technical tests and market tests by the best judges possible – youngsters eating their yoghurt on the run. In 2006, the container hit the shelves.

Fluid control technology

Two other Inveratek products now making the world sit up and take notice are ProFlow and VeraSeal.

ProFlow is a fluid control technology that employs the same operating principle as a conventional ball valve. However, flow is controlled by rotating the actuation system unit itself, eliminating the need for a bulky external actuator.

Inveratek applied the concept to a bottle top that opens and closes with a simple twist using very little torque. The twist top uses over 55 percent less plastic than a standard top, delivers twice the flow rate and provides a better seal.

The VeraSeal technology is the result of one of the world’s largest dairy processors presenting Inveratek with a challenge in July 2005. The company wanted to improve the quality of seal in their HDPE milk bottles.

Explains Adams: “We researched current closure technology, analysed existing bottling and manufacturing processes and discussed our conclusions with blow moulding specialists. It became clear to us the root of the problem was the inconsistent neck finish caused by the blow moulding process. Jarring or placing pressure on the bottle would only increase leakage further.

“Using this information, we developed VeraSeal technology, a significant improvement in seal integrity of threaded closures for blow-molded bottles,” he says.

Lateral thinking

With at least six other exciting innovations now at the whiteboard stage and two major announcements to come within the next few months, the team is excited and enthusiastic about the direction the company is going.

“We have some crazy ideas – but that’s what comes from thinking laterally, outside the box. That’s where CrushPak, ProFlow and VeraSeal came from. We see ideas coming out of weird places – one person’s garbage is another person’s treasure,” says Mitchell.

“CrushPak technology started Inveratek on the road to developing other products or taking other people’s ideas and making them work. The concepts we are now putting through their places on our idea factory floor will revolutionise everything from the way power is produced to the way we make cars,” Mitchell says.

This month the team is heading to Las Vegas, where it will attend PACK EXPO, and then on to Cologne, where it will attend ANUGA – another international packaging expo. In November, Scott will update a flexible packaging conference in London on Inveratek’s work – a perfect example of Kiwi ingenuity taking on board global best practises and sharing home-grown excellence with the rest of the world.

For more information visit www.inveratek.com