IN A market where both consumers and retailers are demanding greater assurance in terms of food quality and safety, protecting and preserving your product at any point in a worldwide supply chain has never been such a critical issue. This is no more so than during the transportation and storage of time and temperature-sensitive perishable goods.

As an industry leader in packaging systems, 3M has developed a number of time temperature solutions to help producers and food processors extend product shelf life, verify product quality and ultimately protect brand image.

A cost effective alternative to reusable temperature monitors requiring calibration is the Temperature Logger TL20 – it combines all the features and technology needed for food shippers to standardise their monitoring around one easy to use system.

The TL20 has a temperature range from minus 20 to plus 60 degrees Celsius, and can be set to monitor a temperature range anywhere within those limits, accurately and reliably recording up to 12,000 data points of time and temperature.

With the simple press of a “check” button, green or red LED lights signal if the shipment has stayed within or gone outside of the pre-set range. The accompanying Temperature Logger Software from 3M offers easy to use detailed graphing and reporting capability and includes a customisable picture window for the insertion of company logos.

Other features include the ability to program variable logging frequencies, optional password protection, re-usability for up to one year, and easy to use functionality. The TL20 is EN 12830 compliant for the transportation and storage of chilled or frozen foods.

Where detailed data logging is not required, 3M MonitorMark Time Temperature Indicators can provide an important temperature exposure measure within the supply chain. MonitorMark Time Temperature Indicators not only signal when a threshold temperature has been exceeded, but also provide an easy to read visual signal to estimate the minimum amount of time a product has spent above the threshold temperature.

Featuring an irreversible high contrast indicator that turns blue as a result of exposure to rising temperatures, MonitorMark provides a permanent record of temperature exposure even after temperatures return to acceptable levels. Placed on or inside secondary shipper boxes of products exhibiting time temperature abuse sensitivity, the indicators provide information to assist in estimating time and temperature exposure, thereby signalling when product quality should be checked.

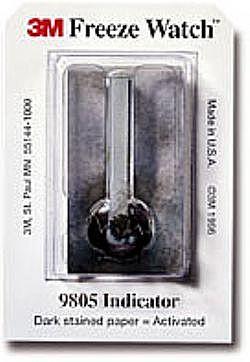

For those companies concerned about potential product damage caused by exposure to freezing temperatures during shipment and storage, 3M Freeze Watch Indicators constitute a reliable freeze alert system.

The patented design of the Freeze Watch Indicators consists of a highly sensitive indicating liquid inside a specially designed ampoule. When exposed to freezing temperatures, the ampoule fractures, releasing the coloured liquid which irreversibly stains an indicator paper.

Monitoring time and temperature-sensitive shipments

General

Wednesday, 28 February 2007