Due to ever higher quality demands and very high availability with few operating and maintenance personnel the requirements here are constantly increasing, which is also reflected in the required qualities of the strip guiding systems and their components.

Determination of the strip centre or edge position

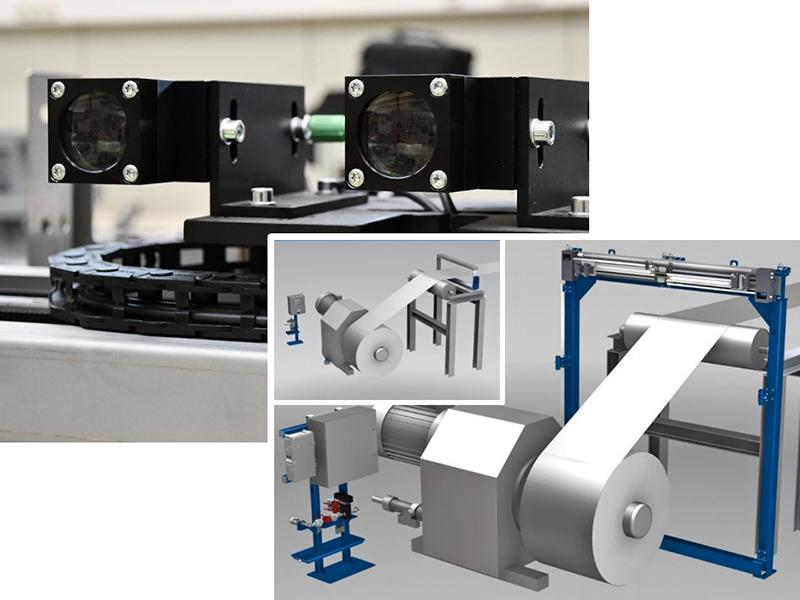

The reliable determination of the strip centre position is always the most important goal for all strip guiding solutions. In general, SMI inductive sensors are the first choice for strip centre control systems. However, their use is limited by the design and the physics of the measurement to the extent that the passage height of the sensor for the strip is limited. Especially during the coiling and uncoiling process, sensors must therefore be used which can reliably detect the strip edge or strip centre from a relatively large distance. The solution in the EMG product portfolio is called "Optical strip edge or strip centre measurement EVK/EVM3". These so- called "receiver adjustment devices" operate with high reliability and are robust against external interferences.

Functional principle:

The strip edge is detected by the movable “receiver adjustment device”, which is equipped with high-frequency (HF) alternating light measuring devices of type LS 13/14 that are protected against ambient light. If a lateral displacement of the strip edge occurs due to changes in width or due to the strip horizontal movement, this displacement is detected by light barriers. The master control electronics then controls either the DC motor for moving the light barriers LS 13/14 (thus following the strip edge position) or the actuator (either a servo valve or an electric servo cylinder) of the control loop. This is always performed until the strip edge covers exactly half of the measuring spot of the measuring light barrier (intensity control).

Special features:

By using high frequency alternating light transmitters, the systems are insensitive to ambient light influences, whether from artificial (e.g. moving light sources on the crane) or natural light sources (e.g. sunlight through the hall skylight). In addition, the reference measuring principle is used to compensate for soiling of the light transmitters.

The new EMG EVK/EVM3 provides:

Improved handling during commissioning

Simplified setting via web browser and digital potentiometers

4 x faster slide LS13/14

Wear-free encoder, better linearity

Long availability of the new generation

New type code

Compatibility with predecessor EMG EVK2/ EVM2

Measuring distance: up to 4 m

Measuring accuracy: +/-1 mm

Typical applications include high-precision demands (e.g., reel, strip centring), large distance applications like coiler and uncoiler controls as well as trimming shears.