Bacterial contamination and undeclared allergens together represent 75 percent of the top FDA food recall causes based on units. With recalls on the rise, it’s no wonder that proactive food safety has become the foremost concern for food and beverage executives, says SKF.

While the broader approach to addressing food safety is top of the priorities, understanding about contamination risks at the component level has been lacking, along with a solution to address it.

Food safety has long been the top-of-mind concern in the food and beverage industry; executives have never taken their eyes off plant-level goals – reducing maintenance downtime, maximising output, limiting waste, etc. The problem is achieving mutual success across all these objectives can be a challenge, especially when suspected improvements in one area inadvertently hinder efforts in another.

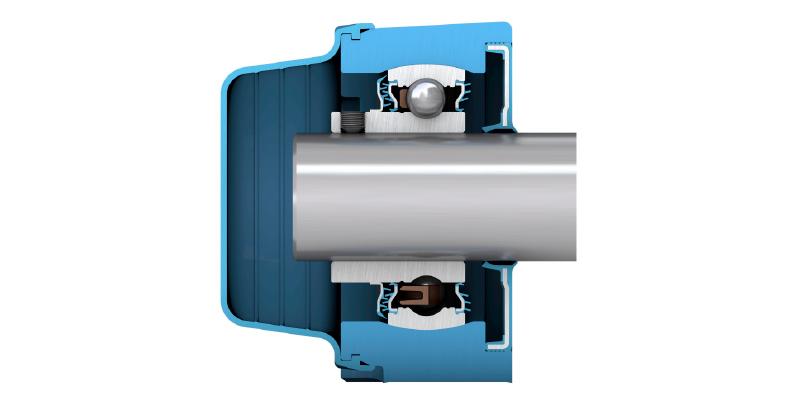

An example, explains SKF, are standard bearing units. These can be a collection point for bacteria and allergens, even in an otherwise hygienically designed machine such as a conveyor. Contaminants can get behind the bearing housing if it is not effectively sealed, creating an environment favourable to bacteria growth. Bacteria and allergens can also collect in the excess grease that results from relubricating bearings. Then when the conveyor belt is cleaned as part of routine maintenance procedures, the proximity of the bearing units means bacterial contaminants can be dispersed onto clean areas such as a hygienic conveyor belt. Once contaminants are in the food zone, they put food products and consumer health at risk.

Purchasing stainless steel machines labelled ‘food grade’ or installing workarounds such as spacer-mounted bearing units, doesn’t necessarily mean safe or clean operations. To truly align food-safety and production efforts, organisations need to examine how every action around the food zone impacts their goals – and extend hygienic-design thinking to every component therein, states SKF.

The average cost of a significant product recall claim in the food and beverage industry averages out to NZD 13 million, not to mention the lasting impact to an organisation’s brand. But to adopt this approach, a company must first address:

• Bacteria and allergen traps in the food zone.

• Preventable production downtime.

• Relubrication maintenance and costs. .

• Environmental waste.

While food and beverage companies follow a variety of safety practices to protect food product, traditional relubrication, washdowns, and dry cleaning of bearing units can create unseen avenues by which contaminants travel and thrive. For example, food residue may get behind bearing units and promote bacteria growth, while aerosol droplets containing food particles, grease, and bacteria can stay in the air for hours and settle after pressure cleaning is complete. To improve food-processing hygiene and compliance with food-safety regulations, organisations must:

• Eliminate contaminant traps with completely sealed and hygienically designed bearing units that promote self-draining and deter soiling.

• Reduce the spread of bacteria and allergens with relubrication-free technology that eliminates grease leakage and spreading to food zones during hygienic cleanings.

• Use food-grade components throughout bearing units – from the material of the housing to the bearing seals and lubricated-for-life bearing grease, which should be allergen-free and food-industry certified.

SKF’s new Food Line ball bearing units have been specifically designed and engineered from the ground-up to uniquely address food and beverage industry requirements around food safety, uptime, cost efficiency, and sustainability.

Through SKF’s ‘ground-breaking’ advancements in bearing unit hygienic design, relubrication-free technology, and complete seal-ability, food and beverage companies are able to extend hygienic-design thinking to every component within their food-processing operations, helping them achieve their most critical food safety goals and contribute to environmental targets. Innovation in bearing performance and reliability translates to increased asset availability and reduced costs.

Details, your local SKF Authorised Distributor or email customerservice.nz@skf.com.