According to the International Energy Agency’s (IEA) World Outlook 2023, the clean energy transition and the rise of electric vehicles (EVs) could lead global demand for fossil fuels to peak before 2030. As nations worldwide shift away from fossil-fuelled engines and towards an electric future, automakers are making a shift of their own — starting with their machine set ups. Here, Swetapadma Mohanty, Senior Development Engineer, Gear Machining at Sandvik Coromant, explores the machining methods that will prove key to automotive’s electric future.

Another prediction made by the IEA is that, also by 2030, the global electric car stock will expand to almost 350 million vehicles. That’s more than 60% of vehicles sold. In order to accommodate for the rise in EVs, automakers are turning to alternative machining methods. One such method is power skiving.

Common gear machining challenges

Before diving into power skiving and its machining considerations, let’s think about the common challenges associated with gear machining. The machining of gears for internal combustion engine (ICE) vehicles and EVs can differ in certain aspects due to the distinct characteristics and requirements of these two types of vehicles. For instance, while ICE vehicles often have complex multi-speed transmissions to optimise power delivery, EVs typically have a single-speed or limited number of fixed gear ratios. Other distinguishing features include torque characteristics, noise and vibration considerations and weight and size constraints.

Machining gears, for any vehicle type, presents several machining challenges. To ensure proper meshing and transmission accuracy, gears require tight tolerances with high machining precision. Gears must also be designed to minimise noise and vibrations during operation in order to maintain batch consistency and ensure tool maintenance is key to achieving high production volumes.

Popular gear machining methods include hobbing, milling, shaping and broaching. However, these methods often have limitations such as lower flexibility in handling various gear types, longer cycle times and challenges with specific gear geometries. Hobbing is particularly popular for cutting spur and helical gears and is most suited to smaller production runs and for producing gears with various tooth profiles. For mass production, gear shaping is a preferred method as it can achieve high dimensional accuracy in shorter cycle times.

But these machining methods are incredibly specialist. Broaching and hobbing, for instance, must be carried out on a specialist machine, with a totally different machine required for shaping. Then there are all the other steps required for successful gear production — milling, turning, finishing, quality inspection and so on. What does that mean for manufacturers? Multiple machines set ups, limited flexibility, lengthened lead times and a costly machining process can all be consequences of a gear machining process that’s not catered to our increasingly electrified world.

Enter power skiving.

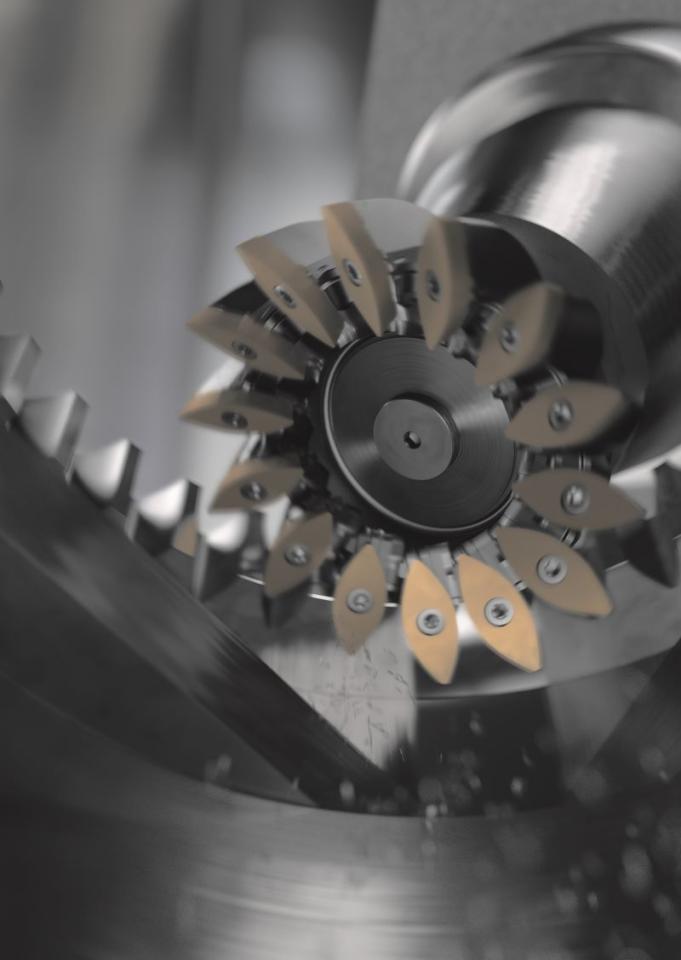

If we’re to get 350 million EVs on our roads by 2030, automakers must turn to machining methods that can accommodate. This is where power skiving comes into play. As a continuous process that uses a specialised cutting tool to remove material from a gear blank, power skiving boasts several benefits over traditional methods like hobbing and shaping.

First, power skiving typically provides higher precision and tighter tolerances compared to traditional process. It’s well-suited for producing gears with complex profiles, including helical gears and non-standard shapes. Traditional process may have limitations in achieving intricate tooth forms, especially when dealing with high helix angles or specific gear geometries.

Generally, power skiving is faster than traditional gear machining processes and, as it removes only the necessary material to form the gear teeth, the waste produced is minimal. A core driver for its use in EV production is power skiving’s flexibility — it’s suitable for various gear applications, including those with specific performance requirements. Manufacturers can therefore adapt to different gear types more easily than they can with traditional machining methods. With reduced set ups in multitask machines with power skiving, higher quality can be reached.

Crucially, power skiving is performed on a multitask machine. Performing multiple activities on a single machine will reduce set up times, improve accuracy, increase throughput and streamline programming. For those currently using multiple machines to execute traditional gear machining methods, however, upgrading to a multitask machine for power skiving requires some investment. It will be up to manufacturers to weigh up the pros and cons of their machining set-up, but there’s one thing we cannot deny — the pace of electrification isn’t going to slow down. To compete in an evolving, competitive market, flexibility, adaptability and process efficiency will be fundamental.

Tool selection

If power skiving is the right machining method for automotive’s future — what are the right tool choices? Let’s start with the gear milling tools themselves. Tools should have tight tolerances to ensure accurate machining and to produce gears with uniform quality. A good gear milling tool should also be heat-resistant to maintain its cutting performance and prevent premature wear, with a design that facilitates proper chip evacuation to ensure smooth cutting operations.

The CoroMill®178 and CoroMill®180 family of gear milling tools meets those expectations. For internal and external gears, capable of machining both cylindrical spur and helical gears from roughing to finishing, CoroMill 178 is an important part of a successful power skiving set-up. It is best used in applications where high volume, high rpm machining with long tool life is required, while CoroMill 180 is best for general use on shoulders or small diameters. These tools offer the highest tool accuracy, regarding run-out and pitch, compared with indexable tools, providing a better finishing profile of the gear and spline.

In one customer success case, by replacing a traditional process with power skiving using CoroMill 178, cutting time was reduced and tool life increased considerably. With an annual increase in production, the customer could save over 100 hours’ worth of machining time per year.

It’s not just about cutting tools with Sandvik Coromant. Customers are offered tooling and application support, as well as a service offer with technical feasibility consultancy. For instance, our ESCO software forms another crucial piece of our power skiving offering, which promises high quality and accuracy production of Power skiving tools.

InvoMilling forms another crucial piece of Sandvik Coromant’s gear machining offering. Part of the CoroPlus® Tool Path software, InvoMilling is a process for machining external gears, splines and straight bevel gears with unmatched flexibility, making it very attractive for small batch production and when short lead times are crucial. The solution benefits from multitask machines and machining centres capability to produce many different gear profiles with the same set of tools.

As the world gears up for an electrified future, automakers must consider their manufacturing techniques. While traditional methods of gear machining have long served the industry, thriving in a changing and increasingly competitive environment demands flexibility. Power skiving offers that flexible, adaptable approach — all while delivering finished components to the highest quality. As market lead Sandvik Coromant also focusing high level of sustainable Power skiving tools and reducing CO2 footprint.