Are your machines safe against falling masses or involuntary movement of parts? For 40 years, SITEMA’s products have protected machine operators and machines during operation or maintenance.

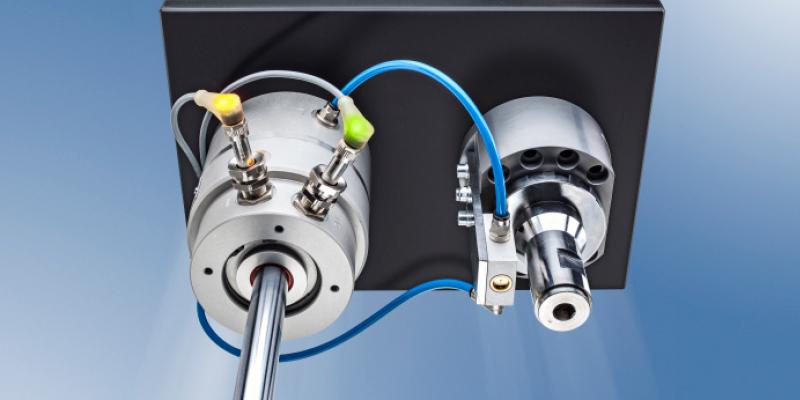

SITEMA’s various clamping head series, all made in Germany, can secure loads or movement (both vertically and horizontally), hold precise positions (e.g. a platform), support parts against a process force (e.g. a movable table against a press force), or even create a high force on a short stroke (e.g. in moulding machines).

From a few hundred kilos to several hundred tonnes, SITEMA clamps can secure them all.

Applications include – but are not limited to – presses, machine tools, production machines, lifting tables, packing machines, palletisers, gantry loaders or even big engines such as tunnel drilling machines or coal crushers.

All that is needed is a round rod to clamp on, and pressure to keep the clamp released in normal machine operation.

Curious? Please have a look at our website, where you will find many examples plus our brand-new interactive 3D application showroom.

Your contact person for New Zealand: Hendrik Bolz

Follow us on LinkedIn and YouTube