|

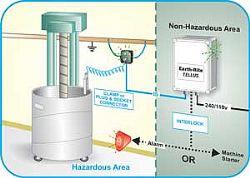

SO MANY fires and explosions around the world can be attributed to static electricity. Static is a recognised “source of ignition” anywhere there is dust, vapours or gas. Recent examples of its danger can be found here and overseas. In the US, ethyl acetate was being pumped from a portable tank on a pallet when a spark occurred due to insufficient bonding. As a result a warehouse was burnt to the ground and two people injured. Closer to home, at the Canterbury Aero Club a fire occurred while a plane was being refueled, probably caused by a spark from static discharge. One person was seriously injured and the plane destroyed. Static is the unseen danger that has the potential to cause serious damage. It is generated in most situations where liquid or powder is flowing through pipelines, hoses, valves, pumps, fans or filters. Static can easily ignite the vapour/air mixture or dust/air mixture. Voltages in excess of 20,000 to 40,000 volts commonly occur when fluid or dust is being transferred or decanted from one container to another or from a tanker to a tank.Road-tankers create their own potential for static by moving through the air and by the friction of the tyres on the road. It is common for a tanker to have 50,000 volts sitting on it after a road journey. The good news is that static is relatively easy to keep under control. Bonding and grounding/earthing all the components of a fluid or dust decanting or transfer operation will remove the possibility of a static build up discharging during the process. Even in temporary fluid transfer situations (drum or container filling) static is a severe risk and bond cables must be used to remove the possibility of a spark. Bonding is a relatively simple process where a cable is connected between the items, such as the drum being filled, and the container the fluid is coming from. The challenge is to know whether the bond is a suitable one with a good connection. Various steps can be taken to ensure safety. First, the clamps at either end must be capable of connecting through any paint or coating on the containers. General purpose ‘alligator’ clips are not reliable or acceptable. There is no guarantee that they can achieve the <10 ohms of resistance needed for a good safe connection. Clamps that are certified for use in hazardous environments are available from reputable suppliers. These have teeth that will provide the quality safe connection required. Other clamps are available that are fitted with an LED to show that a good connection has been made. When the light is on there is a solid connection to ground (an electrical earth). For an even more reliable method, where further variables are removed from the safety equation, the failsafe solution is to use a system that interlocks the pumping device so that pumping cannot begin until a safe connection has been made.

|

On road-tankers similar techniques can be employed. The tanker must be bonded to ground (earth connection) before discharge can begin. Tests recently have shown that bonding cables and retractable leads on many tankers are not providing protection even though the operator religiously connects them. Cables have broken wire strands in them or the brushes in the retractable cable reels have worn away. The safest solution for tanker discharge is the interlocked control that will not allow discharge until a good ground connection has been established. When the green light is on the pump will run. If anti-static systems are in place they must be regularly checked for safety. Footwear, a source of static build up around sites, should be checked weekly. Especially in areas where powder, or heavier than air vapours are present. Footwear is a known source of ignition and the correct footwear should be worn to minimise the risk. Clamps should have a visual check every time they are used and teeth changed (removable teeth in clamps is a huge advantage) as they wear. Cables should be checked every three months at least, and fixed systems annually. Electricians should check site earthing systems to ensure that the point the cables are being connected to is at the same electrical potential as the other earthed electrical equipment around the site. The aim is to keep the resistance of the bonding connections to <10 ohms. |