|

WHEN Aaron Bryant moved back to New Zealand after living overseas for 18 plus years, he noticed that infrared cameras had yet to become a mainstream tool in the building industry. He was also looking for a career change.

“With a background of running my own successful construction company in Toronto for many years I was not to keen on working for others and wanted a new challenge.”

So Bryant started from scratch, researching and studying thermography, quickly deciding that in the next few years he could see it being used a lot more.

“After purchasing my first camera, a FLIR, and completing a Level 1 training course, which has since been augmented by a number of online courses and further study, I started knocking on doors. The company, Infrared Solutions Ltd, has grown from there.

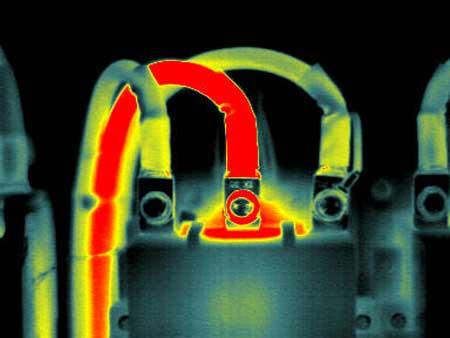

“Most of our work is in the electrical and mechanical predictive maintenance fields with the remainder of our business in residential and commercial building applications such as moisture/water leaks and heat loss inspections. We typically design and implement an inspection routine for our clients to fulfil their insurance policy compliance or predictive maintenance needs.”

Bryant’s inspection work has had its interesting moments. There was a job for a local vineyard when he was hired to find wasp nests along a river bank. “After a bit of research on Google we learnt that wasp nests are under ground and can be up to a metre square in size full of wasps generating heat, which we hoped to see as a hot spot on the ground. We did find two nests which showed up as quite hot at the small openings. But I think at least the larger of the two could have been found simply by following the wasps – nevertheless, I didn’t get stung and the client was happy!

“Then there was the cousin who wanted me to have a look at her horses under the understanding that I could show her hot and cold areas but not what they meant. Sure enough we found two horses with issues: one hot (hind leg bruise) and one cold (bad circulation in knee). One of the horses was rested for a couple of months and came back faster than ever and had a couple of paying results!”

Bryant now has a new project taking up his time which he believes has enormous implications for predictive maintenance. Infrared Solutions is testing a UAV (unmanned aerial vehicle) equipped with HD video and/or IR camera.

“The number of applications are multiplying on an almost daily basis. With up to a five kg payload we will be able to add environmental sensors to collect a wide range of data to go along with our video and infrared imaging.

“Our UAV has autonomous GPS flight, which means we will program it with an exact route by laptop – and, more importantly, for regular inspections we will be able to follow the exact same course and take the same images at the same distances each time.”

Bryant says size options depend on the application, with the smallest electric UAV having a diameter of approximately 600mm yet still equipped with a full featured infrared camera. The larger gas powered UAV will have a flight time of up to two hours and fly into and back from hazardous locations without putting anyone in harms way.

“It’s a much more cost efficient and environmentally friendlier way to inspect those hard to reach or hazardous locations. Infrared applications include powerline inspections in built up areas, any electrical inspection on site at height, roofing system heat loss or water leaks, and so on.

“Other applications include all forms of visual inspections at height or in hazardous conditions – things like chimney stacks or concrete and steel component wear and tear on bridges.”

Bryant says they are currently looking for test sites to trial their gas powered UAV to fine tune their offering. If you can allow access for a trial email aaron@infraredsolutions.co.nz.

Meantime, Bryant is hot on the need for training and ISO certification for IR camera operators in New Zealand to protect the market.

“There are a number of environmental factors to consider and object parameters to take into account when doing an infrared inspection; any one of which can change your image and affect your final analysis.

|

“I can see the infrared industry moving more mainstream in the next few years with reduced camera costs, trade awareness of its abilities and insurance companies being the driving factors. I think we will see predictive maintenance becoming a much higher priority for companies as we move from a nation that traditionally has had the ‘we will use it until it breaks, then fix it’ mentality, to one of keeping the factories working non-stop by replacing components just before they break and avoiding costly downtime.

“However, I think there is also a need for a New Zealand association to monitor and help the industry grow and to protect the consumer from cowboys.”

Enquiries: Aaron Bryant

ITC Certified Thermographer

Infrared Solutions Ltd

2 Trent St

Napier

Ph 027-223-7858

www.infraredsolutions.co.nz

|