The superior performance of the O6 range of miniature photoelectric sensors from ifm electronic has led to their widespread use in a short space of time, and now there are even more places where they can be seen, says the manufacturer.

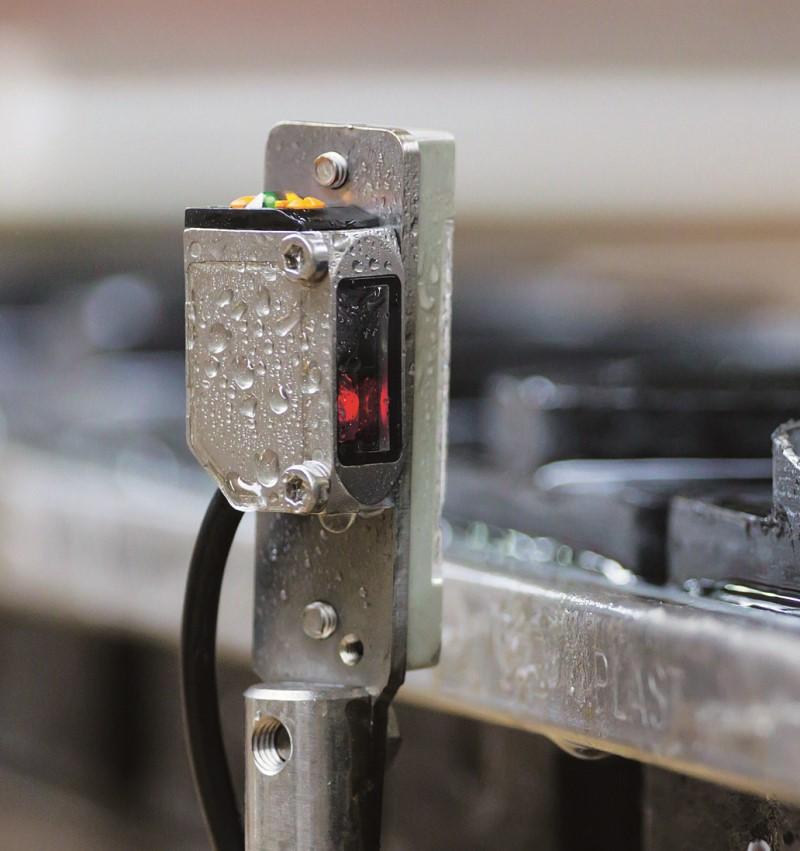

While standard photocells struggle when soaked in oils and coolants, the new O6 400 Series is designed and tested specifically to withstand such aggressive media. A rugged stainless-steel housing provides the first line of defence, with scratch-resistant glass optics and oilproof seals providing an impenetrable fortress.

The O6 400 Series, in a housing with standard 1” mounting centres, is available in four sensing configurations with PNP and NPN versions released. The through-beam and retro-reflective versions provide long range sensing with 10m and 5m respectively, while the diffuse sensor will detect objects at 600mm. Probably the best-performing background suppressed sensor on the market, the O6H, will sense reliably at 200mm without any influence of background materials, however reflective – including high-visibility clothing.

All versions are sealed up to IP68 (which to ifm means extended testing in coolants, in this case) and are supplied with M8 connectors, for which ifm electronic offers suitable mating cables from the EVC range, also rated for coolant.

Details, ifm NZ support: Ph. 0800 803444, sales.nz@ifm.com