Turck offers versatile Profinet absolute encoders for precise positioning and fast data transmission.

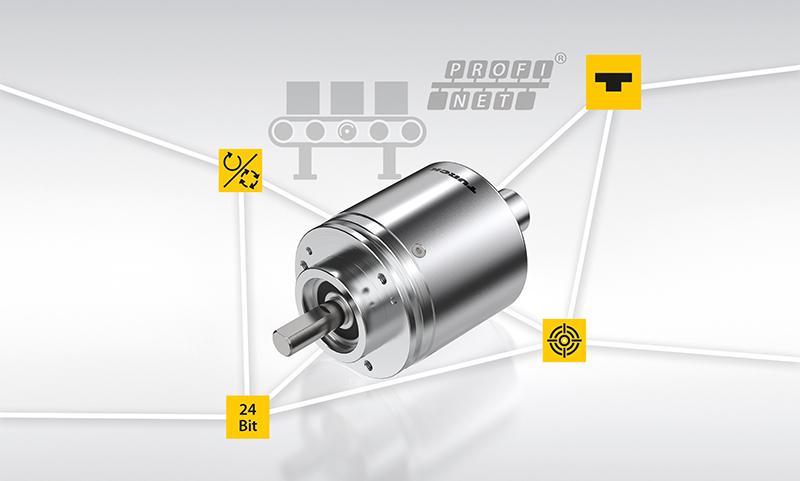

Turck is expanding its encoder portfolio to include encoders with a Profinet interface for real-time applications, particularly in the logistics, food & beverage and machine building sectors. The REM (multiturn) and RES (single-turn) series encoders rely on the latest Profinet encoder profile (version 4.2) and offer 19-bit resolution for the single-turn devices and resolution of up to 24 bits for the multiturn devices. All encoders support Profinet features such as the Media Redundancy Protocol (MRP), Link Layer Discovery Protocol (LLDP) and Simple Network Management Protocol (SNMP).

The encoders ensure precise and virtually delay-free communication even in highly dynamic applications, thanks to the isochronous real-time mode (IRT) and minimum clock cycles of up to 250 microseconds. Their exceptional precision means that the encoders enable highly accurate positioning and speed control, making them ideal for applications such as multi-axis positioning.

The Profinet encoders are available in solid or hollow shaft variants and offer a wide range of configuration options. With different shaft diameters and flange types, they can be optimally matched to the specific requirements of each application. Easy integration into Profinet networks enables fast commissioning and configuration.

Web: www.turck.com.au