THREADED rods come in many diameters, lengths, materials and finishes. Known as headless fasteners, they have a wide variety of uses; Steelmasters offers a vast array from stock as well as a fast turnaround on custom products.

On threaded rod the thread can be the whole length or on one or both ends (single or double ends). Threads can be either left hand or right hand, and they can be produced by cutting or rolling.

The cutting process dictates that material is removed from full diameter bar, whereas rolling is a cold forming process (it does not remove any material) and commences with a smaller bar diameter of approximately pitch diameter.

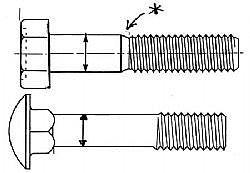

If you look carefully at a standard hexagon head bolt you can see taper into the thread where the shank has been extruded down to allow the thread to be rolled up to diameter*. On a cup head bolt the bare shank is smaller (thread roll diameter) than the thread.

The thread rolling process involves one, two or sometimes three dies with grooves to form threads, or in some cases knurls. As pressure is applied the feed stock is forced into the grooves on the dies and as the dies turn the thread is roll formed. Bolt machines usually have one stationary die and one reciprocating, while threaded rod rollers will have two or three dies, all of which are in motion.

Advantages of thread rolling over cutting include:

Material savings as no material is removed.

Cold working produces a thread which most agree is ten to 20 percent stronger, due to the grain being uninterrupted.

The surface finish of a rolled thread is harder (and often smoother) than a cut thread offering greater wear resistance.

Threads can be rolled at high speeds (much faster than cutting).

The process is accurate and uniform.

Steelmasters supplies a full range of threaded rod, and single and double bolt ends, in standard sizes from stock. Further specials can be manufactured to order in most materials and finishes at short notice. The availability of feed stock for thread rolling may limit options for the less common threads.

(Article by Wayne Mackwood of Steelmasters)