Cranes are a key piece of infrastructure in distribution centres (DCs) and warehouses, ensuring items are handled correctly and safely, and dispatched quickly. The average crane consists of multiple moving parts and relies on a geared motor drive to keep it working optimally. It’s not surprising that current market demand is for drive solutions that can not only handle high loads, but also have a long service life. Harry Singh, National Sales Manager for Bonfiglioli Australia, shares that the company’s HDP series remains popular in overhead applications, such as gantry cranes and bridge cranes, because they have the capacity for large loads, offering an output torque range up to 210,000 Nm and are designed to work hard and offer a long service life. “The service factor on these gearboxes is high and so far, we haven’t had a single failure in the last 25 years with this product.”

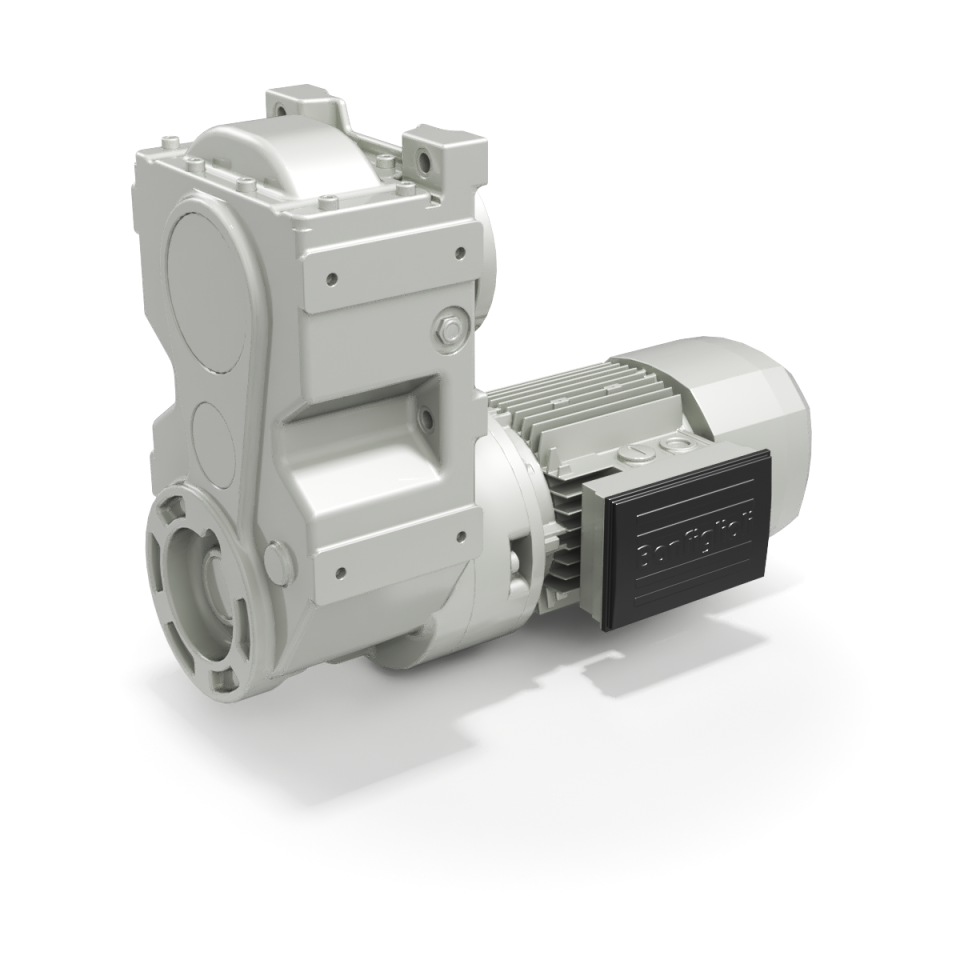

Yet it’s the company’s latest development - the HF Series gearbox – that has received especially positive response from the local market in the last two years. “The HF series was developed for cranes with 500kg to 7 tonne capacities and is ideal for small warehouses and factories. It boasts a unique double safety feature - a motor with a brake inside it as well as the option to add a secondary brake at the back of the drive,” says Harry. “This year, we’ve doubled turnover on this product locally.”

Capabilities that extend beyond the warehouse

Bonfiglioli drives are used in diverse material handling applications. The company most recently supplied drives for the WestConnex project (near the Anzac bridge in Sydney) for the tunnelling.

Harry explains that in these applications, the tunnelling cranes have two functions – moving the frames that support the tunnel shaft, making it possible for heavy machinery to move through the tunnel; and removing the excavated material out of the tunnel and onto trucks. “This work requires larger 100-tonne cranes capable of fast speeds, and 550-tonne units for slow speed tasks”.

Extending the lifespan of key equipment

“Most customers typically request a gearbox with a lifespan between two to three years for a tunnel project, or a maximum of five years,” adds Harry. “However, we design everything with a minimum lifespan of five years. This service life can easily reach 10 years if the crane is maintained properly with regular maintenance and oil changes”.

This is where a maintenance plan proves especially valuable, ensuring that any unusual wear, vibrations, noise or oil leakage are addressed. “Some customers have been running gearboxes in the crane for more than 25-30 years without a problem, thanks to regular maintenance and oil changes.”

Harry explains that quarterly maintenance on crane systems is usually carried out in situ, while every five years Bonfiglioli will remove the drive from the crane for an inspection and overhaul by a certified repair centre to ensure sure it meets Bonfiglioli’s strict quality specifications.

“During a 12-month check, they take an oil sample from the gearbox and get an external third party to assess it for any impurities or abnormalities in the oil, and report back to us,” explains Harry. “After five years, they send the gearbox back to Bonfiglioli for a major overhaul. This involves stripping the gearbox down to its individual componentry and checking everything carefully. We change all the bearings and seals, inspect each gear stage internally, rebuild it, repair it if necessary and deliver it back to the client. It’ll be good for another five to 10 years, thanks to this comprehensive servicing”.

Supporting market growth

To ensure that it meets growing demand for its solutions, Bonfiglioli has taken the necessary measures to ensure the availability of stock locally. “Even large HDP series gearboxes can be built within one to two working days,” he says.

The company recently expanded its local facilities, including its workshops in Sydney and New Zealand, with the aim of increasing stock holding and improving lead times. “Our extensive network, comprising branches in Melbourne, Brisbane and Perth as well as over 90 distributor and resellers across Australia, allow us to support our customers with prompt service,” adds Harry.

“We look forward to the growth of heavy industries in Australia and are well positioned to meet demand for class-leading engineering solutions that drive efficiency, productivity and performance,” concludes Harry.

https://www.bonfiglioli.com/australia/en