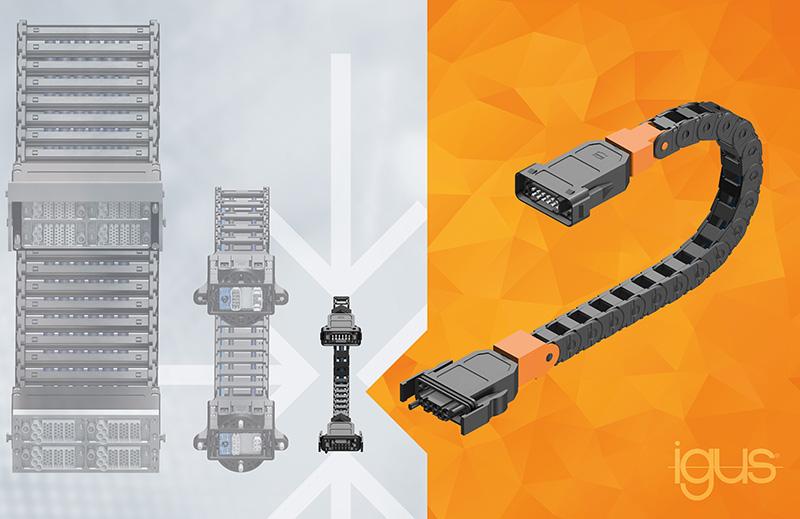

Plug-in principle of the readychain micro-speed enables fast connection of e-chain systems in tight installation spaces

The plug-in igus energy chain system readychain speed from Treotham connects harnessed e-chain systems in seconds and without the use of tools. This helps reduce both throughput times in assembly and machine downtimes, and also brings planned maintenance work to a minimum. The ready-to-connect e-chain system thus saves 80% installation time. With the new readychain micro-speed, this is now also possible for very small applications and in particularly tight installation spaces.

No matter which industry, which country or which company: if a cable in a machine is defective, leading to machine failure, the resulting downtime and consequential costs can be considerable. After all, just a few minutes of downtime often costs companies several thousand dollars. With the ready-to-connect igus readychain speed from Treotham, the e-chain system can be replaced very easily and quickly in these cases, and the machine can start operation again immediately. For very narrow installation spaces, Treotham now offers the readychain micro-speed model.

Cables can be quickly replaced like the power cord of a laptop

With the new readychain micro-speed, Treotham is expanding the solution portfolio of fast plug-in igus energy chains. Thanks to its compactness, with a width and inner height of just 20 millimetres each, the system is particularly suitable for applications where space is at a premium, such as door interlocks in machine tools. With the readychain micro-speed, it is not necessary to separate cores from the terminal strips using tools before changing a cable. This is due to the fact that the connectors are integrated in the energy chain and the cable is already connected on both sides. Thus, the entire assembly is designed to be pluggable. The counterpart, an add-on housing with bushing, can be flanged to the machine housing. If a change is now required, the e-chain can be replaced as quickly as the power cord of a laptop using the plug-in principle - without tools, without know-how, without technicians. Any employee can perform this task without having to worry about making mistakes. Markus Hüffel, Product Manager of readychain at igus, points out: "Thanks to this flexibility, the response speed increases in case of failures, so that downtimes can be reduced many times over. And that's with a small investment."

Customised system for individual moving applications

With the readychain micro-speed, customers receive an interface solution tailored precisely to their application. It is virtually freely configurable and, like the larger readychain speed, can be combined with cables from the wide range of igus chainflex cables from Treotham - including power cables, bus cables, Ethernet cables and fibre optic cables. The cables are protected from mechanical damage thanks to the e-chain. "The required connectors, housings and connections can be planned individually", Hüffel emphasises. "This way, the customer obtains everything from a single source, and each energy chain becomes a tailor-made product."