Getac has announced the launch of the next-generation F110-EX, an ATEX & IECEx Zone 2/22 certified version of its powerful yet versatile F110 fully rugged tablet, aimed at professionals working in/around hazardous environments. The launch means Getac now offers ATEX & IECEx certified options for three of its popular Windows-based rugged tablets – UX10-EX, F110-EX and K120-EX – for customers looking to digitally transform key aspects of their operations.

Powerful performance

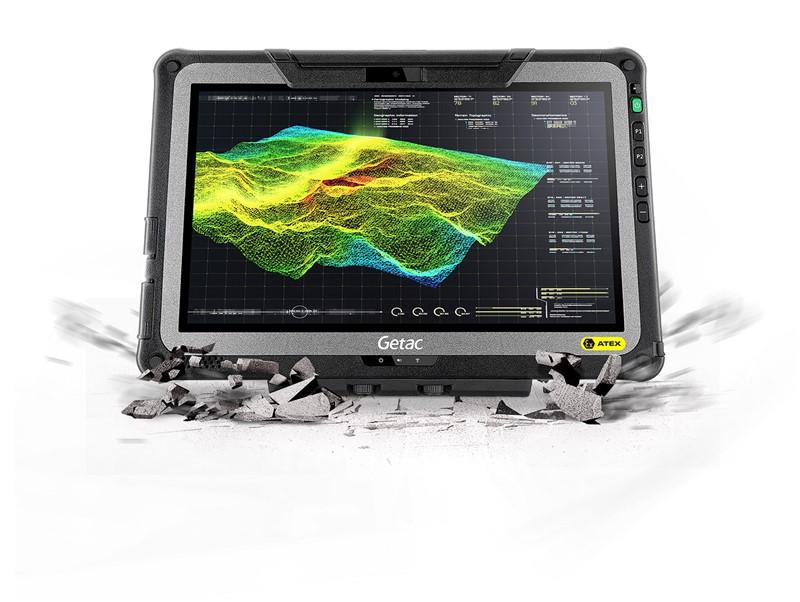

The F110-EX boasts the same powerful specification as the recently unveiled next-generation F110. Features include an 11th generation Intel® Core™ Processor with integrated Iris® Xe Graphics, PCIe NVMe SSD storage as default, WLAN Wi-Fi 6 for 3x faster data speed over previous generations, Bluetooth 5.2 and 4G LTE WWAN. An integrated ThunderboltTM 4 port provides a 40 Gb/s connection for expanded end-to-end solution capabilities, while its 11.6” LumiBond® 2.0 screen offers exceptional brightness (1000 nits) and readability in all weather conditions.

Intrinsically safe design

On top of this, the F110-EX features a range of intrinsically safe design elements that enable it to meet stringent ATEX & IECEx certification standards for use in Zone 2/22 hazardous environments. These include rubber coverings on all ports, guide pins and exposed metal parts, enclosed connectors and screen protection, helping to eliminate the risk of electrical sparks that could potentially ignite explosive atmospheres.

Built rugged from the ground up

Like all Getac devices, the F110-EX is also built rugged from the ground up. MIL-STD-810H and IP66 certification, drop resistance from four feet while in use and an operating temperature range of -21°C to +60°C (-6°F to 140°F) all provide further peace of mind and help optimise user productivity.

The ideal solution for hazardous work environments

The F110-EX’s rugged performance, compact form factor and intrinsically safe design make it ideally suited to professionals working in challenging, potentially hazardous environments such as those found in the mining, oil and gas, chemical and manufacturing industries. Below is a series of potential use cases:

· Mining – mineshaft safety inspections

Safety plays a huge role in mining operations, where the potential presence of flammable gases or dust can pose major challenges. The F110-EX’s intrinsically safe design, wide operational temperature range, rugged reliability, and long battery life make it ideally suited to key tasks like mine shaft inspection, helping to keep workers safe while they carry out their duties.

· Oil and Gas – site surveying and data collection

Digital data collection and analysis is a key part of modern oil and gas operations, helping to optimise productivity, manage assets and avoid unplanned downtime. The F110-EX’s 11.6” sunlight readable screen, optional barcode/ radio-frequency identification (RFID) reader, full high definition (FHD) webcam, and 8MP rear camera simplify field data collection, while optional GPS and powerful connectivity options make sending/receiving information from remote sites quick and easy.

· Manufacturing – chemical and pharmaceutical plant monitoring

Chemical and pharmaceutical manufacturing can be tough on IT equipment, while many facilities often carry the added risk of explosive gas or dust potentially being present. The F110-EX’s rugged reliability and powerful connectivity help maximise operational efficiency at all times, while its intrinsically safe technology protects employees from explosive hazards in ATEX & IECEx Zone 2/22 environments.

Rick Hwang, president, Getac Technology Corporation, said, “Worker safety must always be a top priority and stringent standards like ATEX & IECEx serve as a strong benchmark for organisations operating in particularly hazardous sectors. Getac's extensive range of fully rugged, ATEX & IECEx Zone 2/22 certified tablets demonstrates our ongoing commitment to worker safety, while also providing customers with a choice of solutions that help them to meet their own unique needs and challenges.”

The F110-EX also comes with Getac’s three-year bumper-to-bumper warranty, covering accidental damage as standard. This industry leading warranty helps customers maintain operational efficiency by getting their devices quickly back up and running without the worry of additional cost or extended downtime should the unexpected happen.