Gates Australia has announced the launch of its new specialised industrial power transmission drive design software, Design Power.

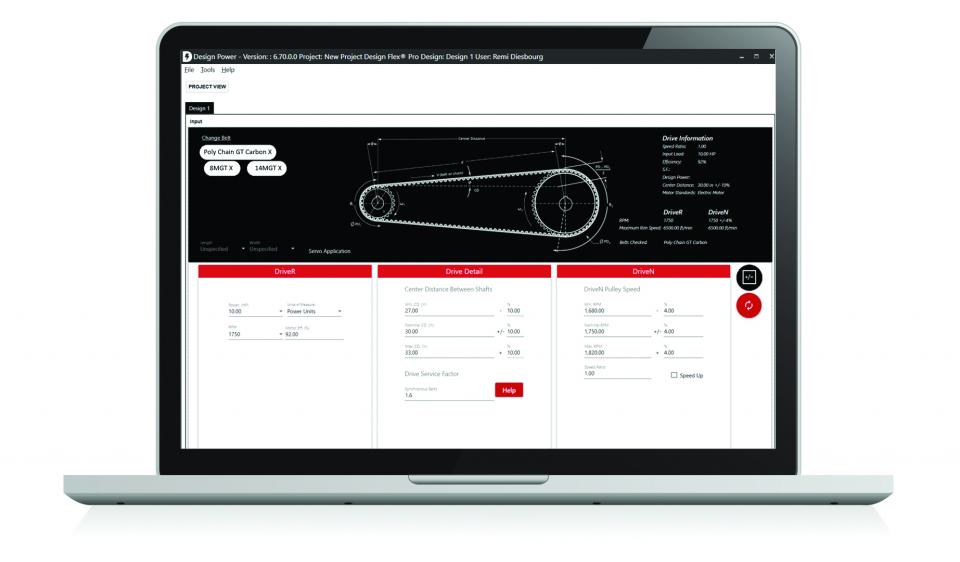

A new proprietary software platform from Gates, Design Power offers multiple digital design tools to support the engineering and specification of belt-drive systems across a broad array of applications, making the process easier and more precise than ever before. Gates Design Power features updated and upgraded versions of Gates Design IQ™ and Design Flex Pro applications.

In addition to the user-friendly functionality of each of the specialised design modules, Design Power includes a state-of-the-art knowledge base with design guidance and the most sophisticated belt performance models.

Automatic synching with the Gates catalog streamlines and empowers the design process with direct access to the latest products, specifications and ratings. Design Power also adds new organisational features on par with the best digital collaboration tools, holding multiple designs in a single project file, tracking design derivatives and iterations, and noting who made what changes along the way.

Design Power has a number of features and benefits including:

- Quickly, easily, and accurately design industrial synchronous or V-belt drive systems that fit your specific design parameters

- Ability to layout complicated belt drives and determine appropriate belt widths

- Easily determine proper belt installation tension

- Calculate belt pull

- Determine the belt power transmission capacity

- Estimate the energy savings of a synchronous belt drive compared to a V-belt drive

- Estimate the cost savings of replacing roller chain with a Poly Chain® GT™ belt drive

To learn more and download the Design Power software, go to visit.gates.com/Design-Power or contact Gates Australia on +61 3 9797 9688 or at salesAUS@gates.com.