Roller chain links reduce drive energy for the E4.1 energy chain series by 37%

Good news for users of the igus E4.1 energy chain series: newly developed roller chain links reduce required drive power by 37%. This allows customers to reduce their electricity costs in times of sharply rising energy prices.

Wholesale electricity prices are skyrocketing. This is a serious challenge to the competitiveness of many industrial companies, so saving electricity is on the agenda. This is true for entire production lines, individual machines or components such as energy chains that guide cables and hoses for energy, data and hydraulics in industrial plants. As a rule, the upper run of an e-chain glides on the lower run. On short routes, energy is not a problem because the igus high-performance plastics from Treotham ensure low-friction operation. For longer travels (several hundred metres) and high payloads (up to 100kg/m), the coefficients of friction increase and, consequentially, energy consumption.

E4.1R: Rolling instead of gliding saves energy

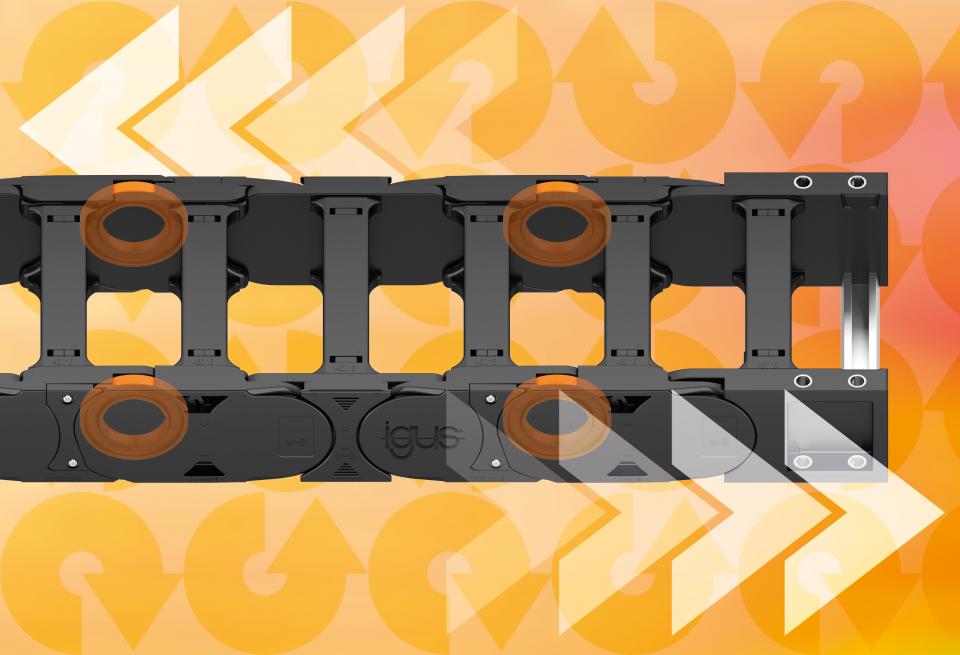

For 20 years, Treotham has been offering igus energy chains for long distances, in which the upper run rolls over the lower run, reducing friction and wear. “Due to rising prices and energy costs, many industrial companies have become interested in cost-saving measures. They ask themselves how operating costs can be cut with the components in use, such as energy chains – especially on long travels with high additional loads”, says Jörg Ottersbach, Head of the e-chains Business Unit at igus. “Our answer is that we also offer a version of our E4.1, the E4.1R, with integrated rollers. This series is one of our best-selling energy chains and a universal solution for 90% of gliding applications.” Rollers reduce drive power by up to 37% – savings that minimise energy requirements now that electricity prices are soaring. A pleasant side effect is that the E4.1R runs more smoothly thanks to the rollers, with noise and vibrations reduced. The roller chain links are also fully compatible with the entire E4.1 series modular system, so that indoor linear robots in the machine tool industry can still be retrofitted, for example. In addition to internal heights of 42 and 56mm, a height of 80mm is available for the E4.1R. Add several widths and radii, and you have a total of over 900 variants for individual applications.

Contact:

Treotham Automation Pty Ltd

1300 65 75 64