Finding and investing in the best laser cutting metals manufacturing machinery is often just the first step in reaping the rewards of a sound purchase in this rapidly expanding and competitive business.

The even more important process afterwards is making the purchase pay by expanding your business using it, ideally by freeing up the time of skilled staff to produce more work for it by producing quotes faster and better tailored to customer needs – thus improving service and

This was the situation in which Melbourne sheet metal building product manufacturer Jonda Pty Ltd found itself after buying a top-line laser cutting machine that enabled it to do the job of cutting material more speedily and accurately – but then finding that was only part of the solution to expanding their business in custom flashing and rainwater goods.

“After purchasing a fibre laser machine, we quickly ran into the issue of not being able to get quotes back to our customers in a timely manner. The manual quoting process was just too time-consuming, which slowed down productivity,” says Jonda Manager, Jake Nikolopoulos.

Jonda’s solution was the online quotation software, ToolBox, from ipCompute (which includes Tempus Tools and ipLaser), which replaces the painfully slow process of manual inputting of data.

ToolBox was developed by laser industry professionals who have a combined 100 years of experience in the laser industry, extending from hands-on work on the cutting floor through to international commercialisation of their technology.

To meet the needs of their global industry, ipCompute's CEO and Co-Founder, Ivan Cooper, and Product Executive, Bruce Thomas, designed ToolBox to more than halve the time and manual input currently required by laser cutting companies to prepare and deliver precise estimates to their own customers.

The Australian-developed laser cutting and fabrication quoting software ToolBox is used by laser cutting and metal manufacturing companies throughout Australia, Europe and the USA to save job shops’ time, and keep quotes accurate and consistent, no matter who is preparing them.

“Getting the fastest and best machine is only half the equation,” says Ivan Cooper. “If you just buy the best machine and stop there, you have only improved half the business. If you let the old manual quotation output method continue to plod along at the same slow pace, you are doing only half the job of growing the business, or less.”

Jake Nikolopoulos agrees 100 per cent – “Using ToolBox, we’re now able to get a personalised and professional looking quote to our customers within minutes, not days,” he says.

“Having our material database and secondary processes like folding, welding, powder coating, electro plating and more all integrated within ToolBox is super-efficient. The whole process from importing drawings to exporting the finished quotes is absolutely effortless.”

“ToolBox has brought our company to a new level of professionalism and efficiency,” says Jake, whose customer response comments reflect the benefits and service the online technology has brought to them.

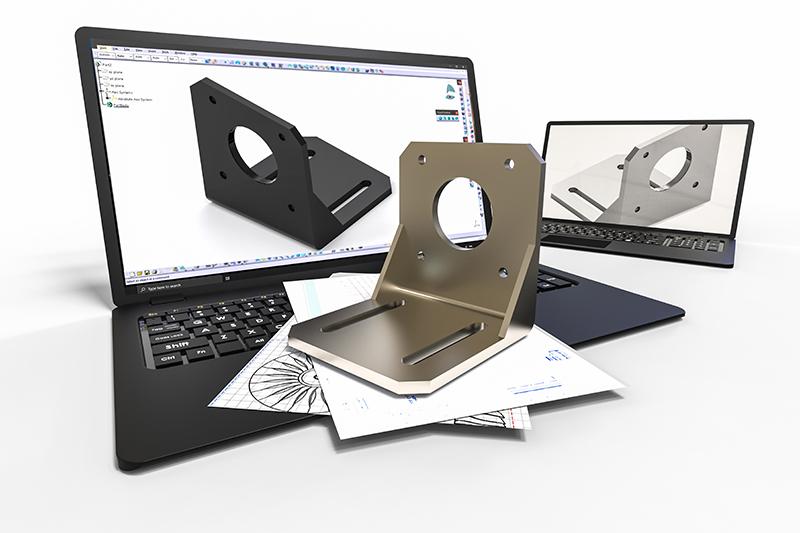

Ivan Cooper says the latest versions of ToolBox technology can turn a CAD drawing into an accurate quote in seconds. The time saved can be used to allow laser job shop staff and resources to be reallocated into areas such as business growth. “The technology is not just a time-saving tool it is essentially a business growth tool, because the time saved allows the energy and knowledge of the business to be transferred into expanding the business.”

“There’s no need to spend hours manually quoting jobs. ToolBox creates estimates in an instant. It enhances customer service by improving response time for estimate requests and increase conversions.”

“It facilitates consistent and predictable quotes to particular customers, so they can rely on prompt and easily comparable prices for the same type of work, which is important in building trust and developing ongoing business.”

ToolBox can also provide an innovative 3D unfolding service, whereby it can be fed full 3D schematics of a product and it will select precisely all the 2D sheet metal surfaces required to be cut by a laser workshop. It’s also possible to create the drawing without using any CAD software, using ToolBox’s Quick Part parametric parts library. Quick Part has a broad range of customisable parts, including brackets, flanges, gussets, and plates that can be adjusted to the specific needs of the user.