Faced with rising costs, supply chain disruptions and labour challenges, manufacturers are working to drive profitability by improving efficiency and productivity, as well as the sustainability of operations. To secure a competitive advantage in today’s complex business environment, the manufacturing sector is seeking out solutions that will enhance performance – including power transmission solutions.

According to Martin Broglia, MD of Bonfiglioli Australia and New Zealand, precision speed control, flexibility of design and technological sophistication top the list of benefits that manufacturers are looking for. “The adoption of new technologies – including automation and digital tools– has been identified as a key growth strategy for the manufacturing sector. But it’s also about investing in high-quality manufacturing equipment – including gearmotors and drives - that deliver versatility, longevity and high performance.”

“The Grant Thornton State of Australian Manufacturing 2023 report highlights that investment in plant and equipment is increasing again since its significant decline during the COVID pandemic. This is a great indication of growing confidence in the manufacturing sector,” adds Broglia.

Efficient material handling with Bonfiglioli conveyor solutions

Earlier this year, Bonfiglioli co-engineered a customised roller conveyor system for Lithuanian customer, UAB VMG Technics (a manufacturer of wooden panels). “VMG Technics had identified that their existing roller conveyor system did not enable them to control the system speed precisely. Bonfiglioli supplied a system that incorporated various C MX Series Helical In-Line Gearmotors with Compact Asynchronous IE3 3-phase motors. These motors were connected to the roller conveyors, and each was controlled by an inverter which was fitted to the machined and connected to a PLC,” explains Broglia. “VMG Technics is now able control the speed of their conveyor system with great precision.”

Unpacking Bonfiglioli’s precision solution

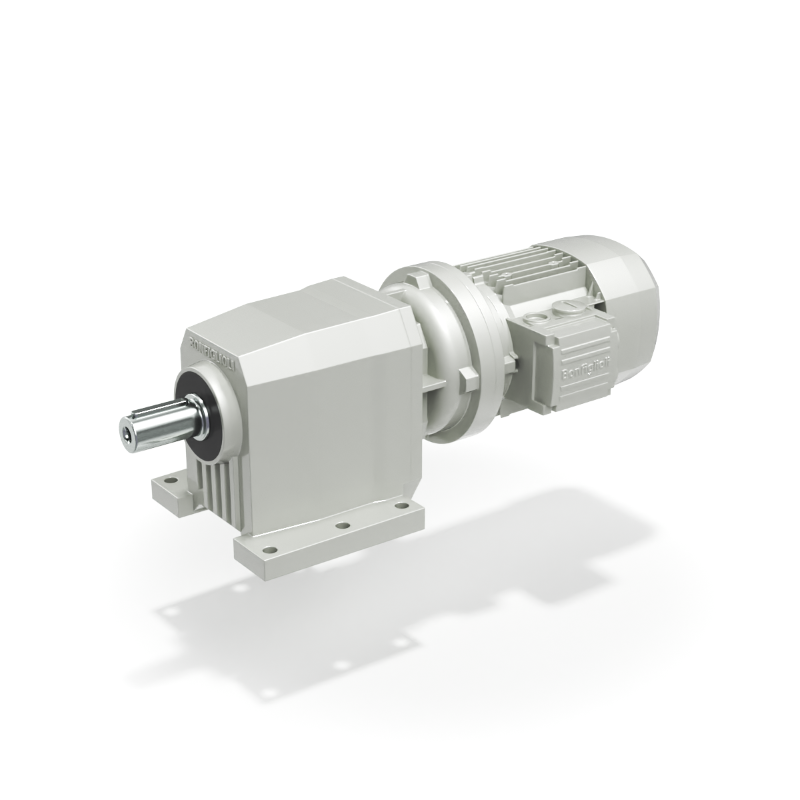

The C MX Series was selected for this customer’s application as it offers a wide output torque range between 45 and 12,000 Nm, and transmissible power of up to 213 KW. “With its wide range of gear ratios, the output speed of the C Series gear motor is easily adapted. In addition, its compact design makes it ideal for use in manufacturing applications, as it requires little space for mounting and offers reduced backlash, as well as energy saving operation,” elaborates Broglia. Coupled with the MX synchronous motors, the C Series is efficient, powerful and reliable.

The DGM-MPM decentralised inverter enables precise sensorless vector control and automatic starting torque optimisation. “When supplied with the gearmotor, Bonfiglioli performs the assembly, wiring and basic programming, reducing both the installation time and the risk of errors,” says Broglia, adding that the company is working to build up local stockholding of these inverters.

“Our motors are designed to integrate seamlessly with the extensive range of gearmotors in our portfolio, ensuring customers don’t have to worry about compatibility between their system components,” concludes Broglia. “This is another reason to partner with Bonfiglioli, in the pursuit of more precise, efficient and productive manufacturing.”