As NASA prepares its first Moon landing in nearly 50 years, the idea of colonising space inches closer. Projections suggest that commercial space travel, space tourism, orbital space stations and lunar habitats could become a reality by 2050. However, to make this possible, technology must withstand the harsh conditions of space including extreme temperatures and the demands of electric propulsion. Here, Chris Johnson, managing director of SMB Bearings, discusses the essential role of precision bearings in making space habitation possible.

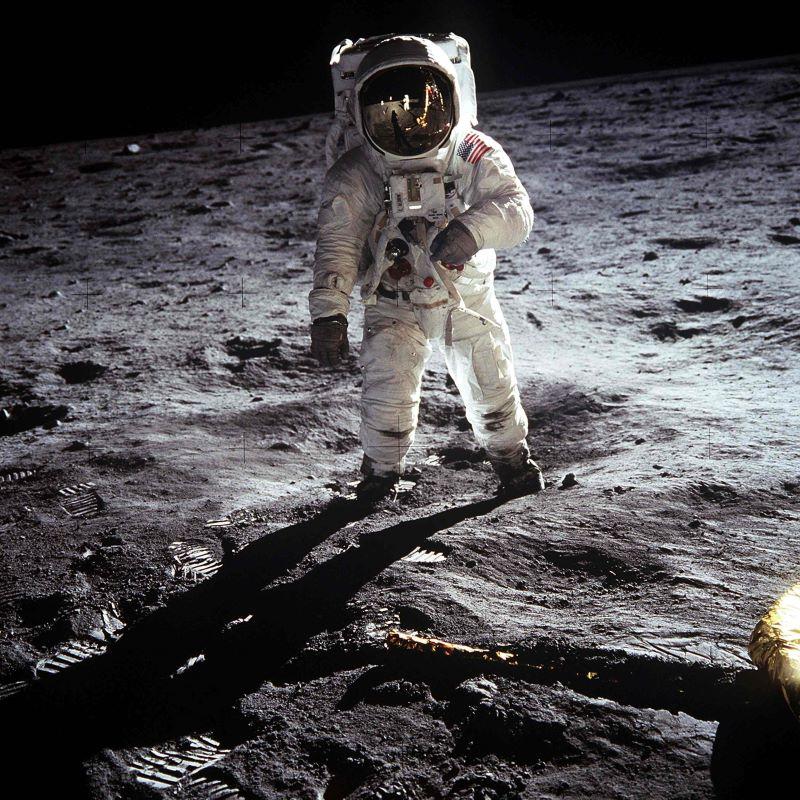

In the decades following the launch of Sputnik 1, the first artificial satellite launched into space by the Soviet Union in 1957, astronauts have travelled to the moon, robotic probes have explored the solar system and spaceborne instruments have discovered a multitude of planets orbiting distant stars. These achievements have laid the groundwork for the next giant leap — a sustained human presence beyond Earth.

NASA has identified the top five technologies needed for a spacecraft to survive in deep space. These include life support systems, efficient propulsion technologies, thermal management, radiation protection and steadfast communication and navigation systems.

Choosing the right component materials for these technologies will be crucial to ensuring they are reliable. Indeed, the primary mission of NASA’s upcoming Artemis 2 lunar mission, scheduled for 2025, will be to confirm that all spacecraft systems operate sustainably in deep space. These components will include precision bearings, which will be integral to the safety and reliability of spacecraft and space habitats.

Deep space applications

Precision bearings for space applications must be designed for high-speed operation and long-term reliability, which will ensure the smooth functioning of propulsion systems, precise trajectory adjustments and efficient use of energy. After all, space technologies face a range of challenges that demand precision engineering solutions for optimal performance. Temperatures in space fluctuate between extreme heat and cold, causing materials to warp, crack or malfunction, jeopardising the integrity of critical systems.

What’s more, the vacuum of space presents a stark contrast to the conditions on Earth. Components must cope with the absence of atmospheric pressure, which can lead to issues like outgassing and material degradation. Precision bearings engineered with tight tolerances and advanced materials are needed that can withstand extreme thermal variations, offering stability and reliability where other components might fail.

Radiation presents another significant challenge. Cosmic rays, solar flares and other sources of radiation can disrupt delicate electronics and compromise mission objectives. In this hazardous environment, precision bearings play a crucial role in safeguarding sensitive equipment, providing a shield against the harmful effects of radiation and preserving the functionality of vital systems.

Furthermore, the demands of propulsion systems in space reiterate the importance of precision bearings. Whether powering ion thrusters, manoeuvring control surfaces or rotating solar arrays, propulsion mechanisms rely on bearings to transmit motion with minimal friction and maximum efficiency.

Safety aboard spacecraft

Whether they will be used in life support mechanisms, propulsion engines or docking systems, designing bearings for space applications presents a unique set of challenges. Extreme temperatures, ranging from scorching heat to cold, test the resilience of materials to their limits. Vacuum conditions strip away the luxury of atmospheric support, demanding components capable of withstanding the vacuum’s grip.

Bearings for space applications should ideally adhere to the Aerospace First Article Inspection Requirement AS9102. The comprehensive guideline encompasses manufacturing processes for a wide spectrum of parts, from small electrical components to large structural assemblies, all crucial within aviation, space and defence sectors.

A part of the AS9100 standard, which is similar to the ISO 9001 quality management system but tailored specifically for aerospace, these stringent regulations set strict engineering requirements on the bearing itself.

Bearing the load

For vacuum applications, bearings with a stainless steel ring, balls and retainer exhibit low outgassing properties. These bearings can be coupled with very low outgassing aerospace lubricants. Rubber seals are not recommended as they will contaminate a vacuum.

Molybdenum Disulfide (MoS2) coatings also play a crucial role in the performance and longevity of bearings used in space applications. In the vacuum of space, where liquid lubricants would evaporate or degrade, MoS2 serves as an effective dry lubricant. It significantly reduces friction between bearing surfaces, enhancing both efficiency and performance.

Moreover, MoS2 provides excellent wear resistance, which is essential for extending the operational life of bearings. Commonly applied to bearing surfaces and used in the lubrication of mechanical systems, MoS2 coatings ensure that critical components remain functional and reliable throughout their mission, making them a necessity for space technology.

Another dry coating frequently used in space applications is tungsten disulphide (WS2) which can be applied to the bearings by sputter coating. Like MoS2, WS2 significantly reduces friction so that bearings can be operated at low speeds with no further lubrication.

PEEK is a low outgassing material often used in vacuum applications, most commonly with full ceramic silicon nitride bearings. PEEK is known for its resistance to high temperatures, chemicals, oils and fuels. PEEK is often used in seals, gaskets and other components where resistance to harsh environments is required. This provides enhanced durability and performance, particularly in extreme conditions, where rubber seals may degrade or contaminate the bearing environment.

Another option is full ceramic silicon nitride bearings. They perform well in a vacuum environment and can be run at low speeds without lubrication, making them ideal for space applications.

As humanity inches closer towards colonising space, the importance of precision engineering becomes more apparent. Precision bearings are crucial for the reliability and safety of spacecraft systems, ensuring that missions can withstand the harsh conditions of space. From life support systems to propulsion mechanisms, these bearings could pave the way for humanity’s next giant leap.